Have you ever had special gearbox applications where the standard catalog specs just didn’t fulfill the need? Perhaps you had to run too fast or had too much torque, or just not enough space for either? Catalog data is not always relevant.

There are a lot of industrial and commercial gearbox applications, and even more in motion control, where comparing catalog performance data just doesn’t provide the correct solution. Why is this?

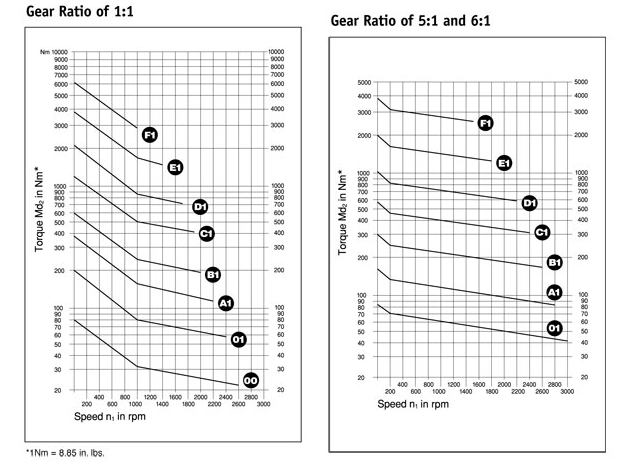

Well, catalog data cannot be calculated for all the potential applications, duty cycles, speed, temperatures, and environments that a particular gearbox may be appropriate for. Because of this, the data is calculated using a specific set of parameters. These parameters usually include 1.0 service factor operation at some given speed, with some specified lifetime.

Why do they do that and why is it important? They do it that way because those are the elements necessary to select bearings, which are usually the limiting factor in gearbox design. It’s bearing life at some load and speed which is most critical in the majority of applications that provide continuous duty. It’s important because it provides a potential basis for comparing manufacturers (although not all use the same criteria which causes more confusion!) and also is a set point to add other operational factors.

So what does this mean? It means that if your application parameters don’t match the catalog calculation parameters then the printed data isn’t relevant.

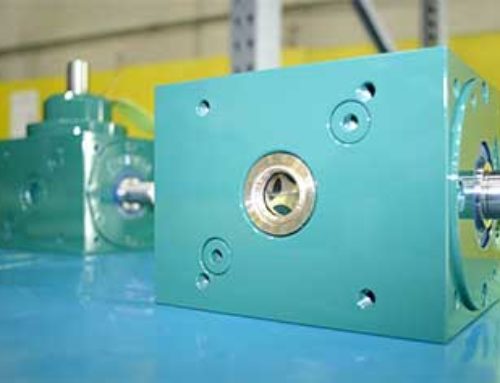

We have tons of examples. The most recent one involves a requirement for a spiral bevel box for an engine test stand. The customer called up and asked for a 30 HP gearbox with a 1:2 speed up with the high-speed side going 5000 rpm.

Now, if you know a little about gears you’ll know that large ones don’t like to go 5000 rpm. Too much oil shear friction and too much shaft seal friction. If you were to look at most catalogs the selection would be for a good-sized gearbox that probably rates at a third the requested speed.

Should we tell the customer to go away? Absolutely not. Further questioning reveals that the gearbox is for a test stand that operates for 30 seconds every half hour and is designed for a maximum of 200 hours of realistic operational life. And to top it off, it’s a cold-weather test with temperatures around zero.

So, at only 200 hours of life instead of the 10,000 hours, we rate our gearboxes at, bearing life and load is no longer the limiting factor. Now it’s gear strength. This allowed us to drop down two gearbox sizes, which also reduces gear pitch line velocity and seal friction.

Both these improvements would allow faster rotational speed if it was necessary. But in this case, we are only operating for 30 seconds at a time instead of the continuous duty used in the catalog ratings. We could probably run 15-20 minutes before reaching critical temperatures at the high speed required. And considering the low ambient temperature, keeping the box cool is even easier.

So, even though the application at face value seemed undoable, we were able to select a standard gearbox that did the job nicely.

The main point to remember here is that the engineering data in gearbox catalogs are reference information only and based on a certain set of circumstances. There are many, many applications with requirements outside these circumstances.

These are the types of gearbox applications where DieQua can be most helpful. With our consultative approach, we drill down to the true application needs. We then use our experience to pick the appropriate gear technology, size, and special options to come up with the optimal solution.

So, instead of just looking in the catalog, give us a call. We’ll get you going in the right direction.