Many machine designers look to use standard components with the idea of saving time and money. But quite often a customized solution can do a better job of achieving both.

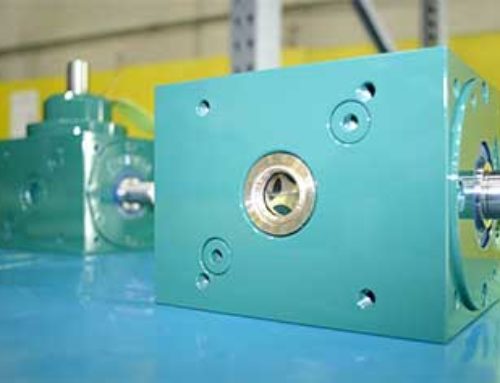

We had a customer using a larger than necessary helical bevel speed reducer because of the requirement of a large output bore. They needed to drive a cooling drum in a plastic extrusion application. In addition to the driving torque, they had to feed a water line through the drum shaft journal to circulate water for the cooling process. To accommodate the water line a larger drum shaft was required than would normally be needed to drive the load.

In this application low backlash was also required so the gearbox was to be shaft mounted and affixed with a shrink disc connection and a torque arm to eliminate box rotation. To further complicate matters there were two sizes of machines, two operating speeds per size, and the possibility of either left hand or right rotation, for a total of eight design possibilities.

To satisfy all these parameters they were using oversized standard products from one of our competitors. This certainly saved time, but the extra costs incurred to purchase larger boxes were a profit eater, and the too frequent errors of ordering wrong hand rotations caused unacceptable production delays. Although a customized solution was an option from their present source, the supplier was a high volume producer that was reluctant to offer specials without hefty up charges.

Being that DieQua specializes in customized solutions using our standard products, this opportunity was right up our alley. The flexible design of our WATT drive product line allowed us to meet all the parameters and deal with tight delivery schedules. In this case we selected a helical bevel design.

Because of some minor internal design differences, we were able to open up the output shaft bore of a smaller, less costly gearbox to an acceptable diameter that could handle the torque transmission and the internal water line. While the modification added cost, it was still less than the larger box presently being used. In this case, customization saved money. Unfortunately, being a special, lead time was going to be a concern. And even with the cost savings, stocking 8 different boxes in anticipation of orders was cost-prohibitive. However, a compromise solution was at hand.

To deal with the left-hand right-hand rotation problem we produced the shrink disc shaft extensions on both sides of the box. Since we were manufacturing a custom shaft anyway, this added very little to the price. The customer could then just move the shrink disc to the appropriate side, away from the machine. An additional benefit was the gearbox was better aligned on the shaft, with the precision bores supporting both ends of the gearbox. While this did add a couple of inches to the overall length of the output shaft, the extra clearance between the box and the machine frame gave the customer some additional room to improve the path of some electrical lines. So a minor disadvantage turned into a positive. This brought the number of gearbox combinations from eight down to four.

This was better, but the high cost of these large boxes still made it risky to stock customized boxes that couldn’t be used elsewhere. To reduce this risk, the next step was taken.

Helical bevel gearboxes are typically made of two or three stages (or more), depending on the ratio. They use a combination of a bevel stage and multiple helical stages, where necessary. The beauty of the WATT drive concept is that it is a modular system, consisting of only 2 or 3 standard “end stages”. The remaining ratio combinations come from swapping out the first stage gearset. Through some minor control changes, the customer was able to slightly modify the overall gear ratios he needed, which allowed us to use the same end-stage for both output speed options. The end result was we only had to inventory two preassembled end stages and a few gears sets to finish all the various combinations of sizes, ratios, and rotations.

While some investment was necessary on the customer’s part, there was a quick payback because of the savings in per-unit costs. And the extended delivery common with customized components was virtually eliminated. We were able to supply a customized gearbox that met the criteria, reduced costs, saved space, and was available in a timely manner.

While a customized solution doesn’t always solve every problem, it can provide design and productivity gains that go beyond just cost savings on the part itself. We often talk about looking at the entire drive system to see where a customized solution can provide overall cost savings or solve a particular design or productivity issue. It is through partnering with our customers to develop a system solution that we can be extremely valuable.

Instead of just comparing a product with a product, the next time you have a gearbox design challenge, contact DieQua Corporation. We may have an innovative idea you didn’t think about or a customized gearbox solution that won’t break your budget.