The benefits of zero backlash, high torsional rigidity, high tilting capacity and compact size are what allow most industrial robots to do what they do, which is to pick and place things very precisely. But it isn’t just robots that need these benefits. Devices as large as machine tools and as small as optical systems need the features that both flex spline and cycloidal gear designs offer in one way or another.

While there are a couple significant players supplying these types of drives, the Spinea’s unique cycloidal gear design provides distinct advantages over the competition. For one, the torque density is unmatched providing more capacity within a given envelope size. This is a result of the unique internal torque transfer components that share loads at greater radii. For mid to large size units, this can tip the balance in our favor over other suppliers of similar products. 10 sizes with acceleration torque capacity as high as 7500 Nm are available.

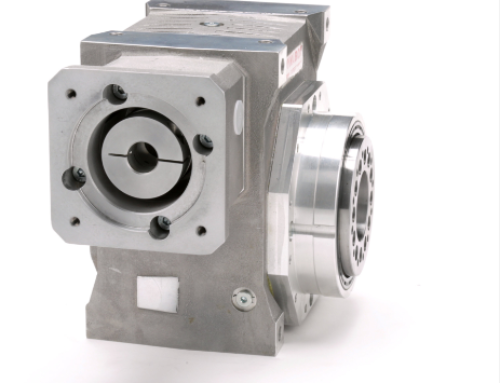

The Spinea TS Series is available in 10 sizes

Perhaps the more significant potential of the unique “Twin Spin” internal design (so named because the flanges on both sides rotate at the same speed with the ratio reduction coming from the central input shaft) is the possibility of creating smaller cycloidal reducers than have previously been commercially possible. Stating that these are the smallest cycloidal reducers in the world is by no means a stretch. Other producers are limited to no less than twice the diameter of the TS 50, with even smaller sizes soon to emerge from Spinea’s R&D department.

Why is this significant? Because the Spinea unit can now compete with flex spline designs, like that produced by Harmonic Drive, but provide much higher performance. The big difference is, comparing a similar diameter, the cycloidal reduction unit can transmit 2-3 times the torque, is significantly more rigid and can support higher tilting moments . A unique solution is now available for a common problem: How to get higher performance in a smaller size.

The Twin Spin design is available in 4 basic configurations for maximum design versatility. These include the T series, which has the smallest diameter, the E series which provides a large diameter mounting flange to better integrate the unit, an H series which provides a hollow through bore for passing wires, lines, etc and M Series, which is the miniature series, soon to include a 40 mm model to go with the existing 50 mm solution.

The Spinea Twin Spin Reduction unit is available in North America from DieQua Corporation along with a variety of other motion control gearing solutions for servo driven applications. DieQua offers the widest range of gearhead technologies along with the experience and expertise to help you select the best one for your needs.