Shaft-phasing gearboxes can be used for more than just registration and timing applications. In this example, the customer discovered a unique application for shaft-phasing gearboxes, using their dual input gear drive design to achieve reciprocating motion, beyond traditional registration and timing applications.

Shaft-phasing gearboxes go by a variety of names – including speed correction drives and timing differentials. The differential moniker came from the original bevel gear designs, with side spider gears, that could be rotated with or against the direction of the main drive gears. This had the effect of speeding up or slowing down the gearbox output speed relative to the fixed input speed. This resulted in the ability to accelerate or decelerate a driven element to move, or phase, it to a new position.

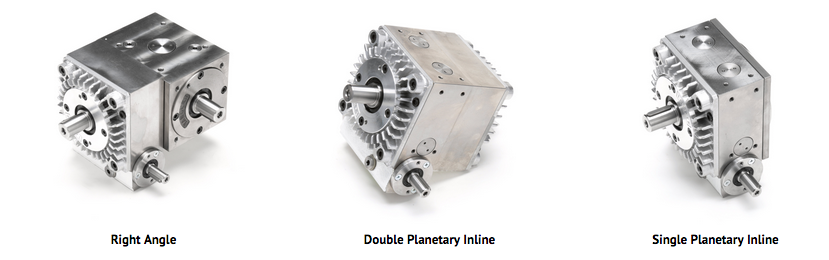

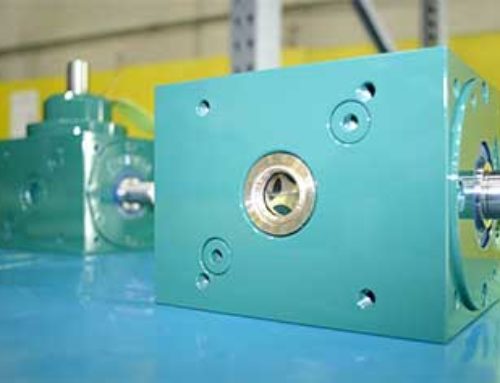

Newer designs use planetary gear designs, with moveable rings, to achieve the same result. This provides a more compact drive and is easier to incorporate with bevel gearing for a right-angle solution. A typical application would be a printing press or another multi-stage process, that requires precise motion and timing from station to station but is driven from a single power source. With a fixed mechanical connection, adjustments at each station are usually difficult. With a shaft-phasing gearbox, a secondary input allows output adjustments independent of the rest of the linked system.

A customer came to us with an application that allowed the use of this technology in an entirely new way. He was designing a relatively simple packaging machine that required synchronized movements of relatively heavy packages. Today many of these types of movements are achieved by servo motor control. However, this customer wanted a more reliable mechanical system. In addition, the torque required to execute the simple motion on the heavy load would have required a large independent servomotor. So he was looking for a different way.

The profile was not complex. A product came into position and a push rod mechanism moved it to the next position. The push rod then retracted to await the next product in the cycle. This continued in a synchronized manner with the other machine workstations. The obvious issue here was that it took a lot of torque to move the load but almost none to retract the push rod mechanism. The question was how to create this reciprocating motion without an expensive, independent servo gearbox.

A key to the solution was that the movement of the load was relatively slow. In a typical phasing gearbox, the correction shaft usually has a very high ratio for extremely precise phase adjustments. But in our case, we offer a variety of ratios so that larger adjustments can be achieved more quickly. It’s this optional ability to make quick adjustments that fit the bill.

Our concept was to take power off the main machine prime mover. There was excess capacity and this provided the synchronized speed with the rest of the machine operations. By connecting the output of a phase box to the pushrod mechanism, we had all the torque we needed to push the load. But how to retract the rod at the end of the stroke? This was achieved by adding a low-power, high-speed motor to the correction shaft.

When the push rod reached the end of its stroke, it activated a limit switch, which in turn started the correction motor. This retarded the output speed of the phase box to zero and then to reverse rotation to withdraw the pushrod back into position. When it reached the home position another limit switch turned off the correct motor, which stopped the phase adjustment, allowing the original gearbox speed and direction to resume, which drove the pushrod to move the next package that entered the station.

In this reciprocating motion design, the input speed and direction of the phase box were continuous, in sync with the rest of the machine. But by using simple limit switches and an inexpensive drive motor, the output shaft could independently be stopped and driven in the reverse direction to achieve the desired result.

While this example of reciprocating motion isn’t a typical application, it is typical of the drive challenges DieQua is presented with every day. While we provide a lot of gearboxes and speed reducers for a lot of standard applications, we specialize in finding new and unique ways of using these products to satisfy specific customer requirements. If you have a particular problem you are trying to solve, there’s a good chance we have a gear product or design concept to help you solve it.