The need for communication and data transfer are growing at a staggering rate. More satellites and more dishes are being put into service on a daily basis to satisfy and utilize the technological advances.

While we have written about satellite dish applications before, there has been a recent explosion of inquiries from various companies producing these products in different sizes. The inquiries include large land-based satellite dish positioning drive designs and mobile applications used by the media, government agencies, and the military.

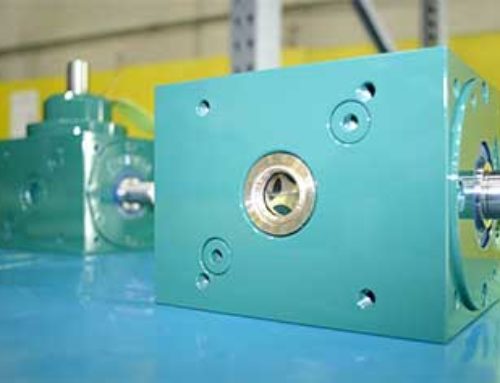

In the most recent applications, the requests have been for system solutions to drive the rotation of the dish. A typical design for mechanical drives in larger systems has the main dish attached to a frame which then has a large “bull gear” around the outside.

Two driving pinions are then positioned on opposite tooth flanks of the bull gear to reduce backlash, thus providing more precise satellite dish positioning. With this concept, only one of the pinions is actually driving the load, depending on which direction the dish is rotating. While virtually zero backlashes could be possible in this instance, the quality and tolerances of the bull gear and pinions would have to be taken into account to determine the optimal gear mesh positioning to avoid cogging and maintain acceptable efficiency.

To best assure consistent rotary motion between the two pinions, at an affordable cost, it’s best to have a mechanical linkage using two pinion drive gearboxes attached with a line shaft. But to get the small incremental movements required, high ratios are required.

Typical pinion gearboxes selected are worm gear designs. In the higher ratios, they aren’t back-drivable, which is a plus in these applications. However, efficiency drops dramatically as ratios increase. So, it is best to get some ratios in a primary driving helical gear motor.

A key consideration in gearbox selection in these types of mechanical drive designs is identifying the torque requirements. This type of application is unique in that the dynamic torque required to rotate the dish is a fraction of the static torque exerted by the force of high winds on the dish. If the gearboxes have to withstand the back driving forces, special calculations for determining mechanical strength can be performed for each gearbox. This is quite different than the standard operational capacity ratings at some given speed over some given lifetime and can result in smaller gearboxes being selected. Catalog ratings are irrelevant in this case.

While worm boxes at higher ratios are resistant to back driving, and sometimes even specified as self-locking, this isn’t guaranteed. Vibration can result in slip movements. With winds buffeting a dish, vibration-like forces can be experienced. Therefore it is often necessary to incorporate a brake somewhere in the system. This can be an independent brake either on the motor, on the line shaft, or on the bull gear. The consideration is that the nearer to the driven load the larger the required brake.

In our most recent application request, the customer’s satellite dish design and space restrictions dictated that we install the brake on the primary gear motor that would drive the assembly. This required the pinion driving worm boxes and main driving inline helical gear motor to withstand the full-back driving forces.

With essentially two different gearboxes in sequence (the two worms considered as one), there was an opportunity to mix and match ratios to achieve not only the desired output speed but to optimize the sizing of the individual drive components. Because of internal design issues, some ratios are stronger than others and some are more efficient. The most efficient, cost-effective, and strongest overall package solution could be offered by selecting specific ratios in both the worms and helical boxes, which affect not only the size of the boxes but also the connecting lineshafts and couplings.

In the latest case, we were able to suggest our Watt Drive H series inline helical gear motor with integral brake, R+W ZAE zero-backlash lineshaft torque tubes in stainless steel and aluminum to mechanically link the three gearboxes, and Girard Dynabox XL precision worm gearboxes with hollow bores and shrink disks to drive the pinions.

Each of these types of data transfer applications, while similar, has unique characteristics. Movement accuracy, speed, safety factors, ambient conditions, and other parameters require each system to be analyzed for its unique needs.

DieQua Corporation specializes in this type of application assistance. With a wide variety of enclosed gear drives and connecting components, along with the experience and know-how to apply them, we are most often involved in the mechanical drive design development of our customer’s assemblies and machines. Wherever motion control or power transmission gearboxes are needed we usually have the product to meet the needs and the recommendations on how best to apply them.