With energy efficiency, a hot topic, designing hybrid power plants for vehicles is growing in popularity and cost-effectiveness. But the gearing necessary requires special consideration.

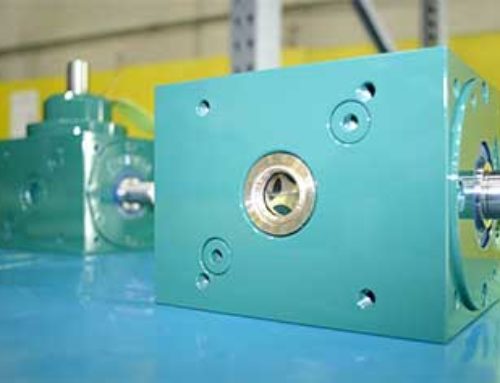

We had a customer recently request a right-angle spiral bevel gear design that was to be incorporated into a hybrid diesel/electrical power package to drive a bus. Much like a train power supply, this hybrid diesel bus engine was to drive a generator that supplied energy to electric motors that powered the vehicle. Designing a gear system to achieve this presented several challenges.

The first challenge is that diesel engines do not provide a smooth and consistent power supply, like that of a typical industrial electric motor. The piston action generates intermittent peak loads that transmit micro shocks and vibration to the drive train. Because of this, it is necessary to apply additional service factors to be sure the mechanical components can withstand the torque variations. But with weight and physical size being a factor, considering the available space in the engine compartment, providing an excessive safety margin was problematic. Calculating the life expectancy was also difficult because the torque utilization varied greatly over the wide speed range that would be seen in daily usage.

To solve this problem, a worst-case cycle profile was established, taking into consideration acceleration, run time at various speeds, and deceleration. Estimating the percentage of run time at each stage allowed calculations of a mean average torque range and a mean average speed. With this data, the proper bearings could be selected to handle the gear separation forces, at the various speeds they were running at, over the expected life of the drive train. Taking into account the diesel power supply, a 2.0 service factor was then added to accommodate the intermittent input torque.

The second challenge was to deal with the rotational speeds required. A 1:2 speed increase was necessary to drive the generators at a sufficient speed to efficiently charge the batteries. The diesel engine speed was to be limited to 2500 rpm, which meant the generators could operate up to 5000 rpm. Because of the high horsepower and size of the gearbox, excessive heat generation was a concern. At high speeds, a gearbox generates a significant amount of heat from seal friction and from oil shear friction through gear churn. At extremely high continuous speeds the oil cannot flow back to the gears, effectively starving the gears of lubrication.

In this case, the maximum speed would only be experienced at acceleration, which would limit the lubrication problem. But the designed cruising speed would still generate more heat than could be dissipated through natural convection from the gearbox surface. The high ambient temperature of the engine compartment added to the problem.

To combat this, two water jacket circulation systems were mounted to two sides of the gearbox housing surface to aid in the heat dissipation. Supply lines were tapped into the engine cooling system to provide a consistent flow of coolant. Temperature and flow rates were calculated by conservatively estimating the expected heat build-up on the gearbox housing surface.

The third challenge was to provide the proper mounting and connection between the engine and the generator. Custom mounting flanges were designed to attach the gearbox to the engine and subsequently to the generator. The input flange had to accommodate space for an elastomeric element coupling to absorb the vibrations from the engine. This was critical as shocks had to be isolated from the generator, Likewise, the output connection was customized as the generator connection required a hollow bore, without backlash, to eliminate connection wear from the torque variations and reversals. To satisfy this we designed a split locking collar that could be secured through an access hole in the side of the mounting flange, some creativity was required in these designs as space was at an extreme premium and serviceability was of prime importance.

In the end, we were able to provide a cost-effective gear drive satisfying the difficult performance parameters within the small envelope allowed.

While many automotive applications experience these demanding criteria, many other industries also see the need for high-speed and heavy-duty cycle solutions. While all standard gearboxes struggle with these requirements and most manufacturers are reluctant to provide specials at reasonable costs, DieQua is both willing and able to handle these kinds of applications. Through years of experience, using premium quality components, and creative designs, we have supplied gearboxes to satisfy some of the most demanding requirements imaginable.

Contact DieQua the next time you’re faced with a gear drive challenge. You may be surprised by what we come up with.