Short-run printing and automated machining require solutions for quick tool changes to achieve customized production efficiently. Two different applications use the same design concept to solve this problem.

In the first application, a manufacturer of printing presses was looking for a quick-connect device to speed up cylinder changes. With short-run printing becoming the norm, print cylinder changeover was eating up a lot of production time.

In the past, a transfer gear was installed on the cylinder shaft journal. However, because of a gear error, some motion variations were created. The new design was to include a direct drive servo motor to improve position control.

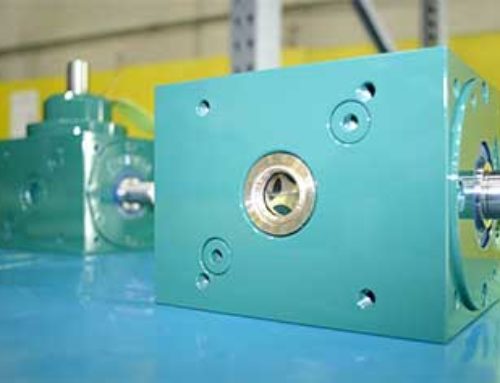

The automated machining solution that we provided was a quick-connect shaft coupling by modifying the taper fit of the bellow coupling. This coupling is a two-piece design with a split hub attached to a stainless steel bellow. The second piece has a conical taper segment that pilots into the bellow. With a small amount of axial preload, a zero-backlash connection is achieved. The conical element is a molded fiber-reinforced polymer material with several driving lobes. This element is then attached to the clamping hub with high-strength adhesive. The overall connection provided a highly rigid zero-backlash torque transmission with misalignment compensation capabilities. With different mating materials, polymer to aluminum, engaging and disengaging the coupling halves was easy and trouble-free.

In this instance, a modified bellow hub with a shaft extension was required to allow the female coupling half to be bearing mounted in the machine side frame. Because R+W provides a wide variety of customizing options, manufacturing the special design was easily accomplished.

A similar solution was offered to another customer that manufactures machine tools. In this case, a standard taper fit coupling satisfied the requirement. The basic design for this quick-connect shaft coupling included a rotary table that presented different tools to be driven by a single power source. Each tool had a male taper segment that engaged the single-driving female segment. Again, a highly rigid, zero-backlash connection was the result, with the addition of connection misalignment compensation.

The R+W series BK5 taper fit coupling can be used in a variety of applications where either a quick connection is needed or where blind mating is required, such as in flanges or areas where bolt-tightening access is difficult. It is a unique design that solves a variety of connection challenges.

The torque capacities of this coupling series range from 0.05 Nm, appropriate for encoders or instrumentation, to 1500 Nm for high torque applications. Additional hub-to-shaft connection styles are offered, based on the needs and desires of the customer.

R+W is a world leader in the design and manufacturing of bellows and elastomer insert shaft couplings. They have the widest range of sizes and design configurations available. Modification and complete customization is a specialty compromising a significant percentage of shipped orders. Their philosophy is to provide a quick-connect shaft coupling that satisfies the customer’s specific needs.

Contact our gearbox consultants at DieQua for an automated machining solution to your next shaft connection challenge. Whether it be a standard product or a completely special design, DieQua is dedicated to finding the answer to your problem.