Customers often call saying they need a gearbox but tell us the application is secret. It’s understandable that privacy can be a concern. But it’s equally important that your supplier really knows what is going on.

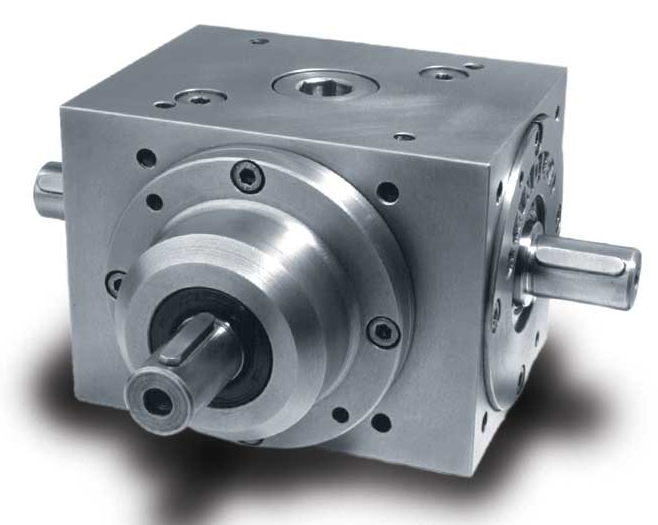

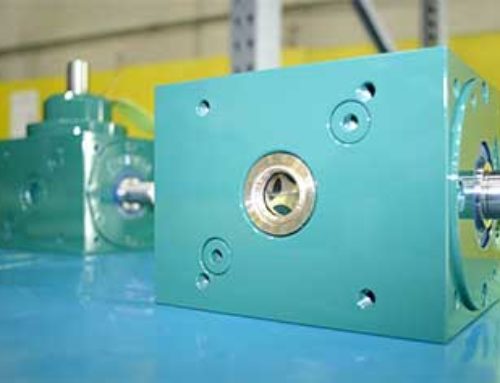

A customer of ours approached us asking for a spiral bevel gearbox that was to be used in a high-temperature environment. They gave us no other information other than the torque required, that all shafts would be mounted horizontal, the speed would be under 100 rpm, and that it had to operate in a high temp environment of 180 C. For the centigrade challenged that is 356 degrees Fahrenheit.

The biggest challenge here was the high temperature. Normally these gearboxes are limited to 200 F operating temperatures when using standard components. Over that things start to melt. Not really until much higher temps, but performance definitely wanes.

The first consideration was sealing the box. Special Viton material, different than standard, was required for shaft seals and o’rings. Because this was a 1:2 speed increaser a special gasket material was necessary for the end plates. This is one of the few ratios that o’rings can’t be used on the output side because of gear geometry.

Grease lubrication was most appropriate because of the slow speed. This was a key help as there were more product options for high-temperature operation.

Selecting high-temperature bearings was of utmost importance. The pinion bearings are typically angular contact ball bearings with a polymer cage separating the balls. This clearly wouldn’t work at the high temperature specified. Therefore a bearing with special cage material was selected.

Unfortunately, this came at a high cost with a substantial lead time, however, it satisfied the customer’s requirements and he was happy with the solution. That was until business picked up faster than expected and our customer’s customers began to demand faster deliveries.

The biggest problem was the delivery time of the special bearing we needed. We couldn’t get them fast enough so we couldn’t deliver gearboxes fast enough. The business was at risk!

Part of the reason we couldn’t deliver faster was that no one wanted to stock expensive, special high-temperature bearings without an order. And the bearing manufacturer didn’t always have them in stock either. So we had to find an alternative.

To try to resolve the dilemma we finally talked the customer into giving us more detailed application data and parameters. What a revelation!

It turned out the gearbox never operated at high temperatures. It only saw the extreme heat in a static state. Its function was to actuate 2 screw jacks that opened and closed doors to a glass furnace so that product could be loaded for the process. The actuation was hand wheel operated when the furnace was off and at much lower temperatures.

This basically meant that the gearbox was over-engineered. We met the parameters that were given to us, but that wasn’t what the customer really needed. By not sharing the complete function the customer could possibly have lost several new orders due to a lack of components!

With the new information, we were quickly able to provide a new design that not only cut the delivery time in half but also reduced the cost by 20%. Talk about a happy customer.

We solved the high-temperature bearing problem by incorporating our standard taper roller bearing option. This is an all-metal bearing that wouldn’t operate well at an extreme temperature but certainly can withstand it in a static state. We use these all the time and have them in stock. Standard Viton seals could also be used, as long as there was no shaft rotation at the highest temperature. These were “standard optional” components as well. This gearbox suddenly became a standard with options instead of a special design.

The learning point here (other than DieQua can supply gearboxes for high-temperature engineering) is that it’s really important to share your goals with your supplier so he can provide the best solution while reducing performance risk. In this case, we were able to provide a simpler solution than the customer originally thought. This turned out to be a big advantage for him. And solved potential future problems for both production and service.

We are happy to sign non-disclosure agreements so that your design innovations are kept in close confidence. The optimal situation is for you to be able to consider us your design partner, an extension of your engineering team. That is certainly what we strive for and it’s one of our major marketing mantras.

If you are looking for a gearbox partner that has your best interest in mind then give DieQua a call. We have the widest range of gearboxes available and the experience and expertise to help you select the best one for your needs.