With more and more labor-intensive operations moving offshore, the ability to automate the manufacturing process is critical for keeping operating costs in check, allowing North American companies to remain competitive in worldwide markets. This has drastically escalated the importance and influence of the entire motion control industry.

In that vein, a customer of ours was designing a transfer system to automatically feed castings into a machining center and needed a motion control solution. The basic system included a large rotary table and two opposing robots to load and unload the table. The need was for a very precise gearbox to rotate the table 180 degrees. In each cycle, a raw casting was loaded on the table as a finished casting was placed on the opposite side. After a half-rotation spin, both castings were removed simultaneously. Then the cycle was repeated.

While we have been involved in several similar designs in the past, this was of substantial size with some specific requirements.

The first was for extreme accuracy in position. When rotated, the casting had to be in a predictable spot so the robot could pick it up and place it in a predetermined area of the machining center. The backlash was to be limited to 1.25 arc minutes so there would be minimal play at the end of the rotation.

Transmission error was also of concern as any inaccurate rotary motion over 180 degrees could possibly alter the expected position by several arc minutes, regardless of the amount of backlash.

Because of space restrictions, a right-angle configuration was requested. Additionally, the length of the input was critical as there was some support framing that had to be dealt with.

The gearbox output connection was to be of a flange style for direct mounting to the underside of the rotary table, as opposed to either a coupled output shaft or hollow bore for external shaft insertion. This was intended to save space and improve rigidity.

Because of the large load and short distance the acceleration profile was relatively slow. Therefore a gearbox ratio of approximately 200:1 was desired to both minimize the servo motor size using mechanical advantage and to operate at the motor’s upper-speed range to enhance resolution.

And finally, based on the acceleration/deceleration profile, along with the inertia of the combined table and castings, a torque value was calculated that needed to be exceeded by close to 200% for safety and a planned cycle time improvement sometime in the future.

A side note is appropriate here to briefly discuss cycle time improvements. As processes improve many customers are able to increase the throughput of their machines by increasing feed rates. Some believe that by increasing acceleration rates by 20% the torque required also increases by 20%. That is a misconception.

To increase cycles with the same components you have to accelerate the load (inertia) faster while doing so in a shorter time frame. With a 20% increase in cycles, the required torque actually goes up by 50%! Most systems weren’t originally designed to handle the additional torque seen in these circumstances. Therefore, always be careful to review the drive component capacities when you are tempted to ratchet up the speed.

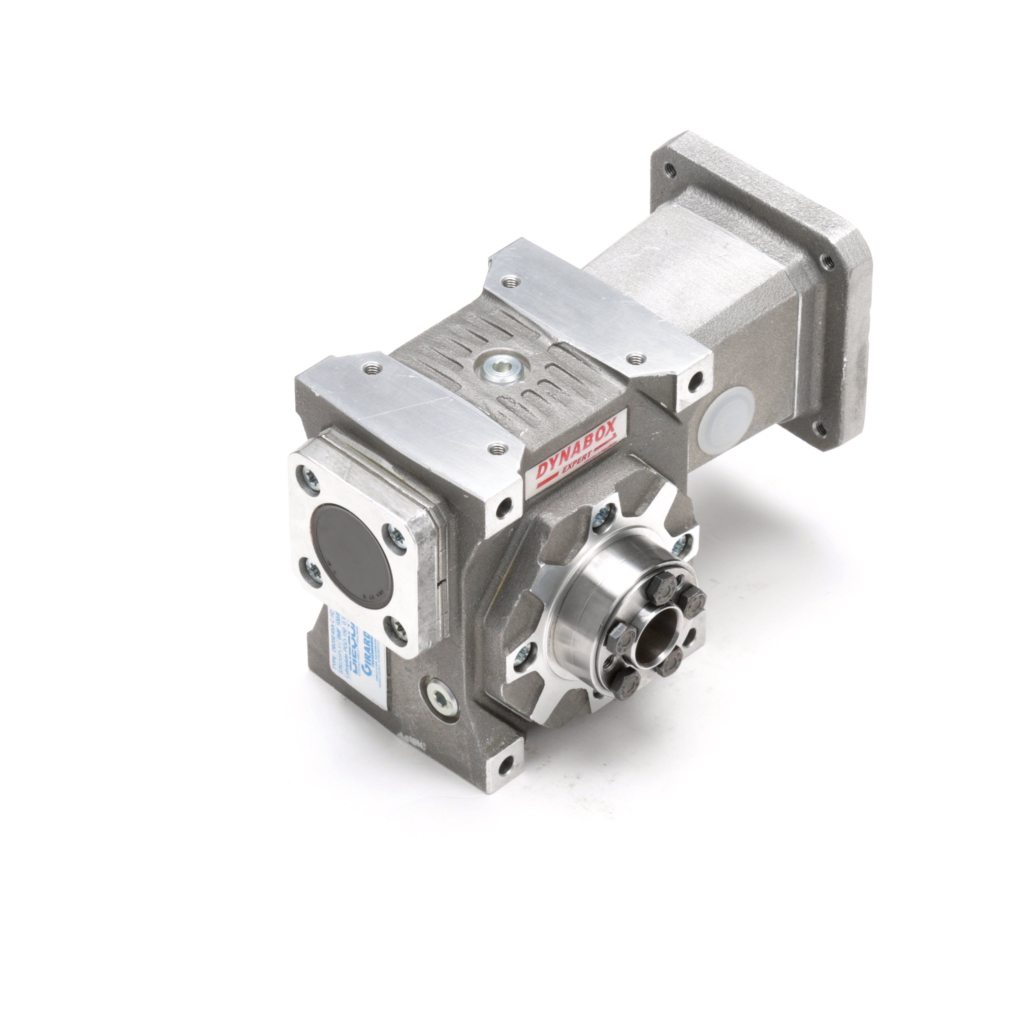

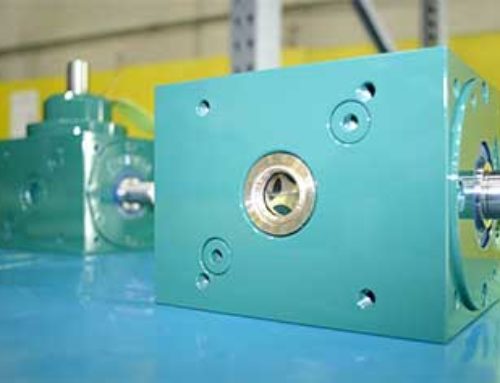

Anyway, back to the application example. While we had a few options that would solve the majority of the requirements there was one solution that was optimal for the job. That was our Dynabox servo worm.

The Dynabox is offered in three backlash levels. The Basic comes in at 10 arc minutes, the Medium at 5, and the Expert at less than 1 arc minute. The Expert can achieve its level with an adjustable dual-pitch worm. In this case, the Expert was the obvious choice. The proprietary ground tooth form also reduces runout, which provides very predictable rotary motion.

Being a worm design it was inherently compact. However, to get the high ratio a double worm was needed. For applications up to 90:1, a single-stage Dynabox could be used. With this ratio and below there is a huge space and cost savings advantage over the typical bevel planetary right angle design offered by most of our competitors.

While in this situation two stages were necessary, offsetting some of the advantages, the versatility of the design allowed us to configure the input to point the servo motor in a direction where space was available. Additional costs were reduced by using a lower priced Basic version with a lower ratio than the first stage box. While higher in backlash the play in the first stage is divided by a factor of the higher ratio in the second stage, virtually eliminating its effect.

Regarding the connection of the box to the rotary table, one of Dynabox’s five output options is a rotary flange (we call it a robot flange) that can be piloted and bolted using multiple patterns. As previously mentioned this reduces output length and improves connection rigidity through integration on a larger diameter.

Sizing a gearbox to the required torque was only a matter of matching the need to the appropriate model. There are 10 sizes offered in the Dynabox family with capacities ranging from a max of 8 Nm in the smallest size to 7000 Nm in the largest. The majority of our applications, however, are in the low to mid torque ranges where the cost-effectiveness of this product now makes considering a right-angle solution more viable.

The customer liked the fact that all his requirements were satisfied without compromise and were available in a standard catalog item. He made the decision to go with us, has built several transfer systems and has already begun designing the Dynabox into other machines. This has been another success story for us as well as our customers.

With such a wide range of gear products and the know-how on when to use them DieQua often is able to satisfy our customer’s specific needs with our standard models. But a big benefit of working with us is our ability to customize our standard products to satisfy a specific desire. In fact, over 50% of our top customers have asked for and received a slightly modified product to meet a unique need they deem necessary to differentiate their design.

Whenever you require a motion control solution or need a gearhead, gearbox, or even an integral gearmotor, give us a call. We won’t try to offer you what we have. We’ll give you exactly what you need.