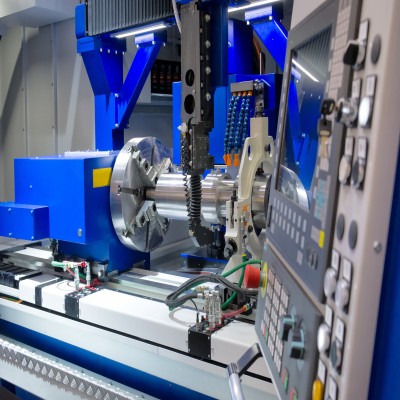

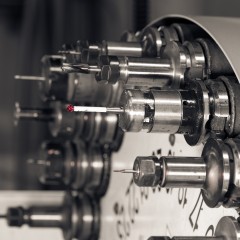

Machine Tools

The TwinSpin high precision reduction gears generally find applications in the machine tool segment in the rotary positioning of tools and workpieces. The most common applications include milling heads, grinding heads, cutting heads, rotary tables, tool and palette changers, etc.

Low vibrations and high torsional and tilting stiffness in combination with high positioning accuracy and low runout of SPINEA’s high precision reduction gears are the key features that ensure high machining precision and excellent quality of the machined surface. All of these advantages positively influence the productivity of a machine.

The compact dimensions of the high precision reduction gears and integrated radial-axial bearings allow to simplify the machine design, to save space, to reduce the assembly time, and to lower the manufacturing costs of machines.

CNC Machining Centers

- High torsional and tilting stiffness

- High positioning precision

- Low runout values

- Low vibrations

- High overload capacity

- Excellent precision throughout the service life

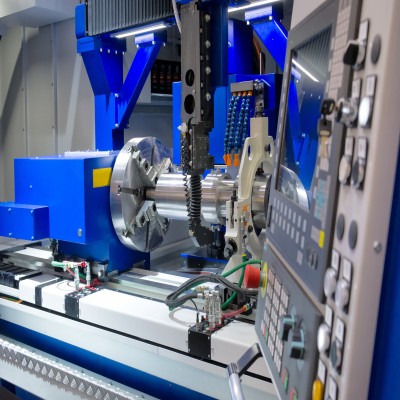

Water, Plasma, Laser Cutting Machines

- High cutting precision

- High cutting efficiency

- Small dimensions of high precision reduction gears for compact design

- High torsional and tilting stiffness

- High quality of the cut surface

Bending Machines

- High torque capacity

- Integrated radial-axial high capacity output bearing

- High flexibility of bending due to compact design

- Low input inertia

- High gear reduction ratio (up to i=191)

- High overload capacity

Grinding Machines

- High positioning precision

- Low runout values

- Excellent precision throughout the service life

- Low vibrations

- High torsional and tilting stiffness

- High gear reduction ratio (up to i=191)

ATC (Automatic Tool Changer)

- High load capacity

- Integrated high radial-axial output bearing

- Compact design for simple installation

- High overload capacity

- Low input inertia

- Maintenance free