The food industry is a complex collective of diverse businesses that supply most of the food consumed by the world. This covers a series of industrial activities directed at the processing, conversion, preparation, preservation, and packaging of food, beverages, and confectioneries. DieQua’s gearbox technology plays an important role in these processes, ensuring standards are met. No matter the application, there are regulations and standards associated with the products used in equipment. Our job as a gearbox manufacturer is to understand what these standards are, so we can either match the stock products or make the appropriate modifications to build products that meet and exceed those standards.

Common Applications

Stainless Steel Spiral Bevel Gearboxes

Stainless Planetary Gearheads

Servo Gearheads

DieQua Benefits

More Products to Serve the Food & Beverage Industry

ZIMM Screw Jack Systems

Zero Backlash Couplings

Gearmotors & Speed Reducers

Customizations

About DieQua

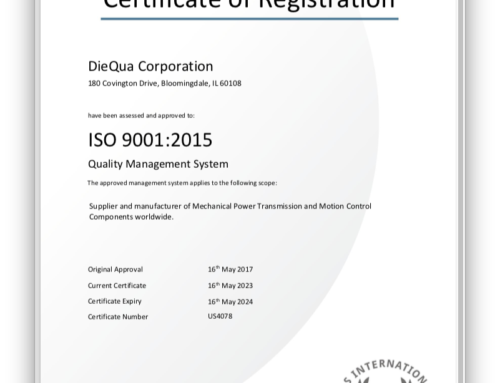

Founded in 1980 by Dietmar Quaas, and now owned by his sons, DieQua Corporation has expanded from a single product line to become a leading manufacturer and supplier of an extensive line of high-quality power transmission and precision motion control products, including gearboxes, servo gearheads, screw jack systems, speed reducers, cycloidal reducers and connecting components. The company also offers custom product modifications and complete design solutions for virtually any application.

An experienced and knowledgeable technical sales, customer service and engineering support staff, as well as local distributors, ensure that DieQua customers in North America, Mexico and South America select the optimum components, systems, and best design solutions for their specific requirements.