Installing some type of torque limiting device in your machine system is very often a wise idea. This is especially true where there is human interaction, but it’s also smart to include them in other types of processing equipment. A common objection to designing them into standard machine designs is that they sometimes cost more than the components they are thought to protect. But that’s really a secondary consideration. The prime reason to add them to machine designs is to eliminate the downtime associated with removing damaged components, finding replacements, and installing new ones. This could typically take days if spare parts are not in stock. The lost production from a single instance could likely pay for every torque limiter in the plant.

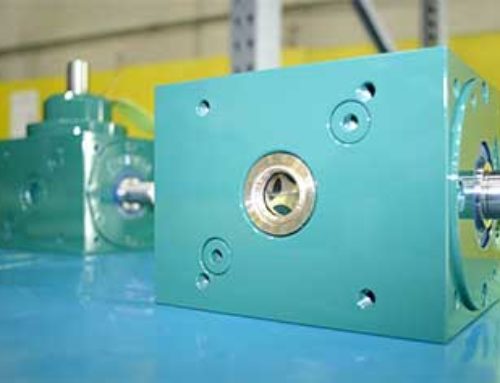

A customer of ours had the recent need for a complete screw jack lifting system that would lift the hood of an industrial oven for cleaning purposes. It was to be raised about once a month for the maintenance procedures that had to be performed. For this discussion, suffice it to say that the entire system was to be driven by a single motor with enough power to lift the hood by jacks in six positions. Because of the low duty and potential for debris build up, there was concern that one of the jacks may jam and all the power would go to a single location. So a torque limiter was desired and installed at the output of the motor to sense an overload and break free before damaging something.

Usually, a torque limiter is most useful closer to the load, but in this case, we couldn’t afford to have one jack disengaged while the others kept lifting. Bending and crunching would likely ensue. It had to be at the motor so the whole system would disengage at the same time. At this point, you are probably asking how a single jack could handle the input torque designed for six jacks if it jammed. We did increase each jack a size so its static safety factor exceeded the nominal torque required to lift the whole load. We also included all the gearboxes, line shafts and couplings to drive the complete system and calculated all the gearbox, jack and guide system efficiencies to size the motor power required to do the job.

So the day came to test the system. They flipped the switch and the torque limiter immediately tripped out. OK, that was strange. All the guides were rechecked and the calculations re-calculated. Everything seemed OK so we tried it again. The torque limiter tripped out again. We thought maybe something was wrong with the torque limiter. So we replaced it with a standard shaft coupling so the customer could try to continue with their test. The start button was pushed and with a slight groan, the hood started lifting.

We took the torque limiter back to the shop for inspection. We then set it up for a test and to our pleasant surprise it worked as planned. So what was causing the problem? We decided to check the motor to see what was going on there. The customer got some monitoring equipment to check the amp draw during operation to verify our power calculations and found something interesting.

Because the power was drawn directly from the main power line, the motor tried to instantaneously accelerate the entire inertia of the system as well as overcome all the frictional elements. As a result, there was a massive current rush and peak torque generated that the torque limiter quickly sensed and then disengaged. Unlike some electronic systems that can be programmed to delay a reaction, mechanical torque limiters are dumb devices that disengage immediately once the desired torque is reached. And this is their greatest advantage: extremely fast disengagement. It should be noted that mechanical torque limiters can be provided with integral flexible elements to be used as couplings or in hub designs for driving pulleys, sprockets, and gears.

The simple solution to the dilemma was to install a soft start to control the motor’s acceleration and starting current draw. This kept the motor torque below the desired disengagement torque setting and the entire system worked flawlessly. There are many elements to a mechanical system that have to be considered. We like to work with our customers very closely on the design process to help assure that the proper decisions are made. That’s a big part of the value proposition we offer.

Let us help you with your next mechanical drive application, whether it’s gear drives, connecting and safety components, or lifting systems. We have the products and experience to make your next project a success.