Speed Correction Gearboxes – Installation & Maintenance Instructions

Congratulations! You have just received one of the highest precision, most durable speed correction gearboxes made. The spiral bevel gearboxes provide low backlash torque transmission, and the speed correction drives allow for precise registration, timing, and narrow range speed control. Please read the following information to maximize the benefits of owning a Tandler gearbox.

Operation

Tandler gearboxes are inspected, tested, and filled with the proper amount and type of oil, ready for operation. The optimal performance of these gearboxes is based on a number of factors including the application of service factors, proper mounting, lubrication, and maintenance procedures. Speed and torque capacities vary by gearbox size and ratio.

The gearbox is designed to operate in an ambient temperature range between -20 °C (-4 F) and + 40 °C (104 F). Carry out regular inspections to ensure that there are no leaks or unusual noises. The operating temperature of the gearboxes must not exceed 80 °C (175 F). Try to avoid exposing the gearbox to direct sunlight or other sources of radiation.

Mounting

Normal mounting assumes all shafts are in a horizontal plane so that all bearings and gears are in the oil bath. If any shafts are in a vertical plane, alternate lubrication options and/or sealed bearings may be necessary.

Connecting the gearbox to the input power and the load also requires critical considerations. When driving with a sprocket, belt, or gear, a radial load calculation must be made to ensure bearing load limits are not exceeded. When connecting with couplings, proper alignment within the coupling specifications are necessary to avoid bearing wear.

Maintenance & Lubrication

Proper maintenance is necessary for getting the optimal performance and longest life out of your gearbox. Standard oil change intervals are after the first 500 hours, then every 2000 hours. Lower duty cycles or the use of synthetic oils may allow for longer change intervals. Continuous high speed or heavy load applications could require shorter change intervals.

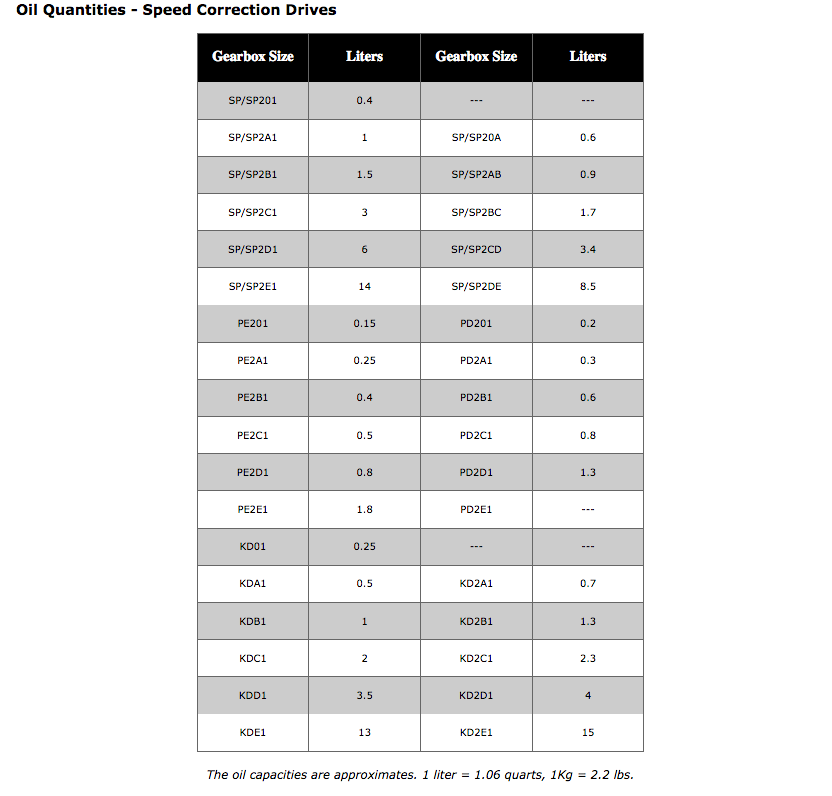

It is also important to maintain the proper oil level. Too little oil results in insufficient lubrication and cooling. Too much oil can cause overheating due to excess shear friction. Standard oil level sight glasses and optional external oil gauges are available to monitor the gearbox oil level.

The oil or grease within the gearbox lubricates and transfers heat to cool the gearbox. The majority of heat is generated by oil shear, bearing friction, and seal friction. During normal operation and speeds, the gears and bearings are adequately lubricated by oil splash and misting. An acceptable temperature range is up to 100° C (212° F), normally seen at maximum design speed. If higher temperatures are being generated, additional cooling methods will be required.

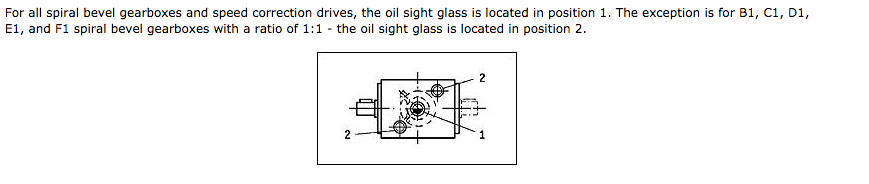

For all spiral bevel gearboxes and speed correction drives, the oil sight glass is located in position 1. The exception is for B1, C1, D1, E1, and F1 spiral bevel gearboxes with a ratio of 1:1 – the oil sight glass is located in position 2.

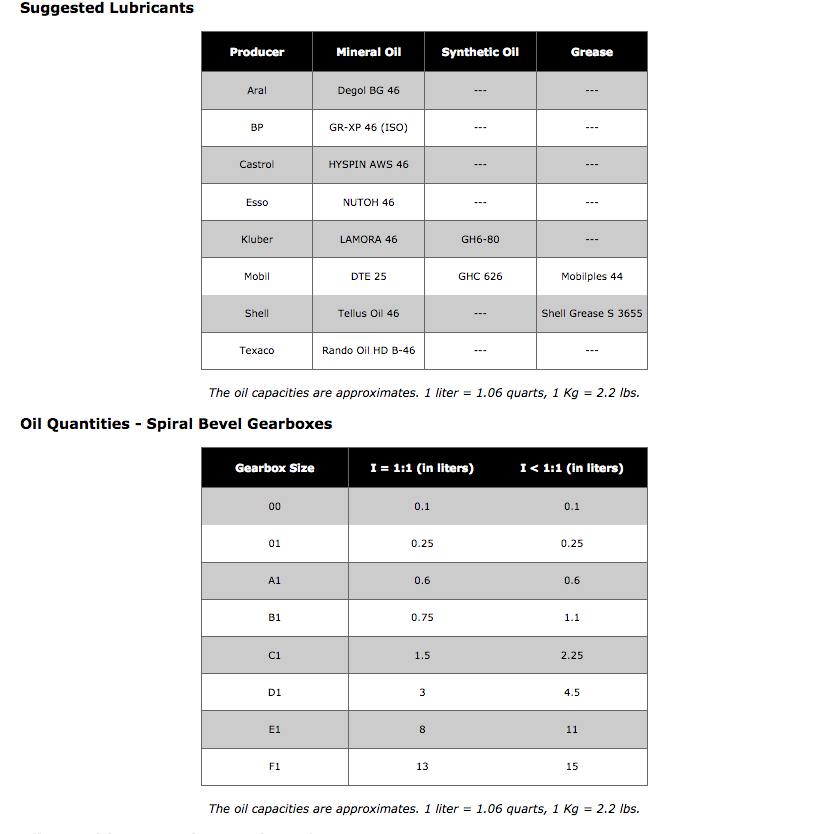

A standard viscosity oil is included with each gearbox. Although alternate oil viscosity can be used, depending on the application, we do not recommend using heavy weight gear oil! This type of oil may cause excessive heat and gear tooth wear.

The lubricant should be changed every 2000 hours but not to exceed every 5000 operating hours (2 years maximum). To avoid the risk of burns, allow the gearbox to cool to room temperature before changing the oil. The waste oil must be disposed of in accordance with local statutory regulations. The oil drain plug must be screwed back firmly into position before refilling with fresh oil. The gearbox must be refilled with mineral gear oil CLP according to DIN 51517-3 ISO VG 68. Grease filled gearboxes are maintenance free. The list below are approved suppliers and types of oil and grease.

Storage

The gearboxes must be stored at ambient temperatures not to exceed 40 °C (100 F), without large variations in temperature and humidity. In high moisture environments, the external corrosion protection must be renewed before storage.

For storage periods longer than 6 months, the unit should be completely filled with the original oil type and sealed. The outer surfaces should be coated with a suitable anti-corrosion compound. If there are fluctuations in storage temperature, water condensation must be avoided.

The gearbox must be protected from sources of radiation and corrosive media.

Safety Precautions

Rotating parts must be protected against accidental contact by the operator, in accordance with the local and statutory regulations. To prevent the risk of burns, the gear housing must not be touched with bare hands at operating temperature. In order to prevent electrostatic charging the gear casing must be grounded.

Complete Repair Services

While spare parts are available, the precision assembly required is recommended to be done by trained personnel. DieQua Corporation offers complete repair services for these products.

In the unlikely event a repair or failure analysis is required, we suggest you send the product back to us. We will evaluate the product, free of charge, and advise you of costs prior to any repair. While standard repairs may take a few weeks, emergency services are always available.

Before returning any products, we request that you call your Sales Support Representative to discuss the problem and receive an RMA number. Documentation will be created and your return will be processed promptly upon receipt.

Sales Support Contact Number: 630-980-1133

All products should be packed securely with connecting components removed. Freight should be prepaid and the RMA number prominently displayed. A representative will call you, after the evaluation is complete, to discuss the proper course of action.