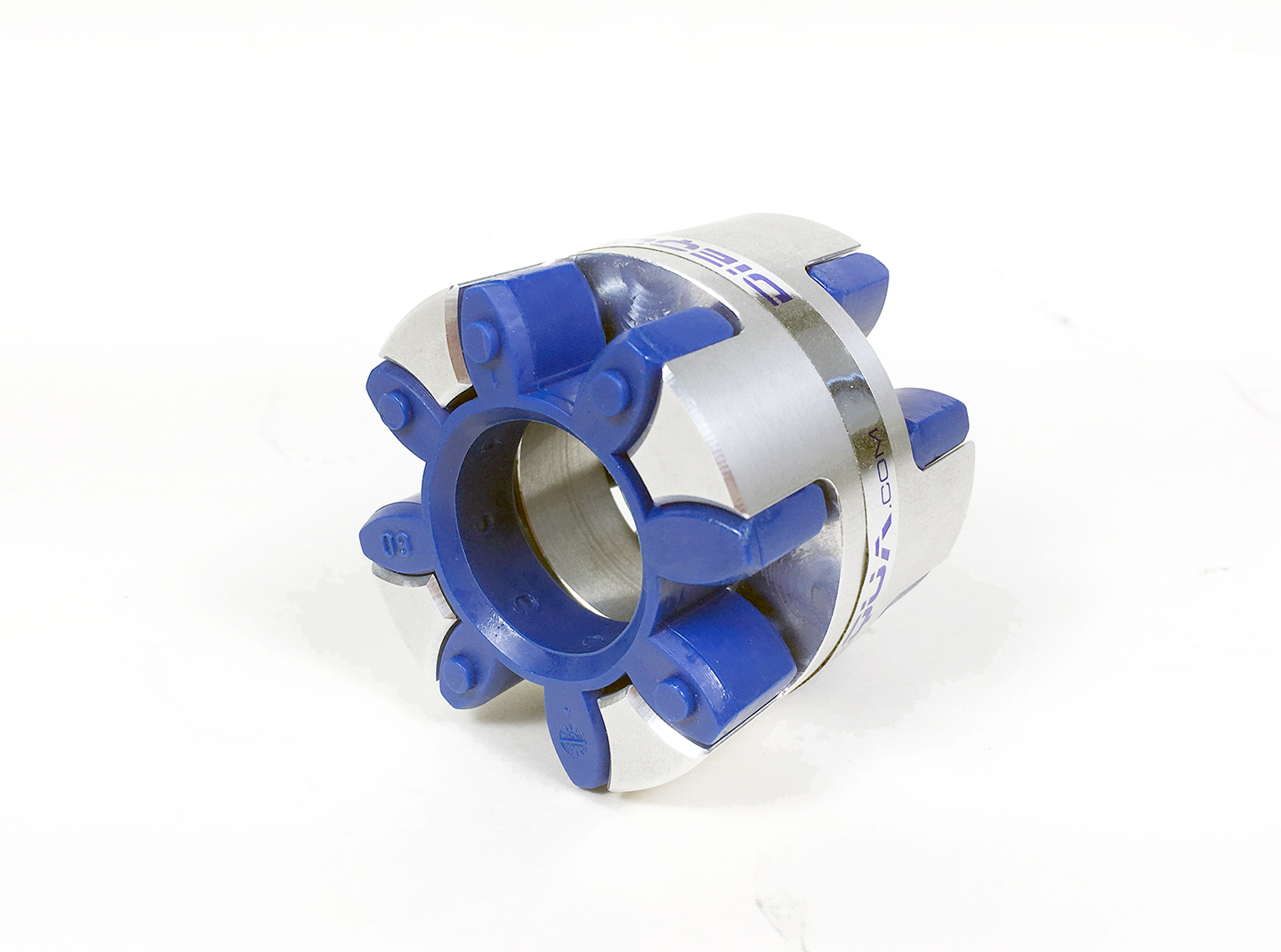

Series EC – Elastomer Insert Jaw Couplings

DieQua offers the EC Series Elastomer Jaw Couplings for those applications that require higher performance than typical insert couplings. These anti-backlash stainless steel jaw couplings provide zero backlash, several clamping styles, and five different insert types that provide varying degrees of torsional rigidity.

- 2 to 660 Nm

- Vibration damping

- Backlash-free Elastomer Jaw Couplings

- Lateral or Hollow Shaft mounting

- 4 Models of Jaw Couplings: Provides a variety of connection options.

- Zero Backlash: Provides exact position and rotary motion.

- Variable Torsional Rigidity: 5 insert shore values provide different stiffness ratings.

- Low Inertia: Allows faster acceleration and deceleration with lower torque.

- Compensates Misalignment: Allows axial, lateral, and angular misalignment for easier mounting.

- Precision Jaws: Concave design concentrically machined.

- Electrical Properties: Insulating or conductive options are available.

- Design Versatility: Mixing and matching hub styles are possible for optimal design solutions.

- Stainless Steel Optional: Stainless steel hubs and bolts available upon request.

- Non-Standard Applications: Custom insert couplings design, with varied dimensions, tolerances, and keyways are available upon request. Also available with ATEX certification for explosion-proof application requirements.

- Download the Catalog

- Download CAD Drawings (See the Charts Below)

- Request more Information

What’s Next?

Elastomer Jaw Coupling Overview:

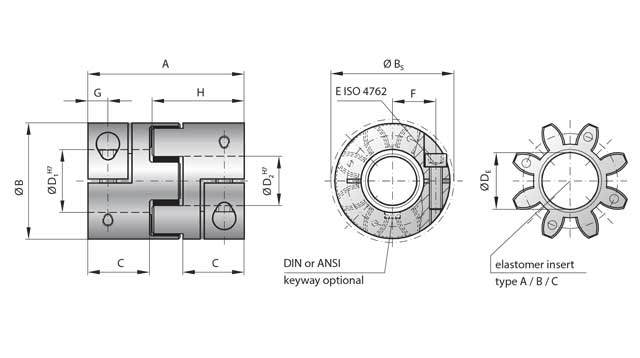

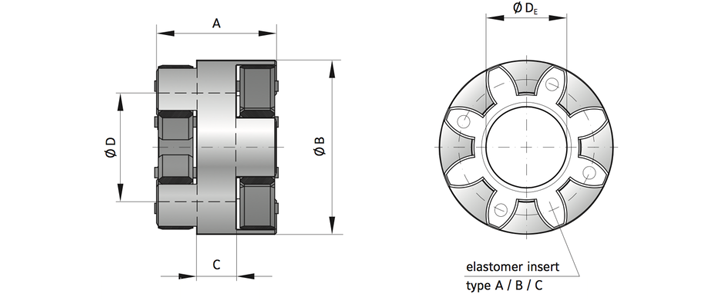

Model EC - Elastomer Insert Coupling with Clamping Hub

Design Description: Two longer concentrically machined hubs with single screw clamping connection. Our most popular model!

Bore Diameters: Metric or inch bores from 8-60 mm, or .314 – 2.36 inches. Keyways are optional, but not necessary.

Hub Materials: Size 20-450 in high-strength aluminum. Stainless steel available for all sizes upon request.

Rated Speed: Up to 10,000 RPM standard. Higher with balancing.

Temperature Range: Download the catalog for Temperature range.

Sizes: EC-20, EC-60, EC-150, EC-300, EC-450

Application Example:

Sizing Chart:

| EC | 20 | 60 | 150 | 300 | 450 | |

|---|---|---|---|---|---|---|

| Type (Elastomer Insert) | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | |

| Rated torque (Nm) | T KN | 17 | 21 | 6 | 60 | 75 | 20 | 160 | 200 | 42 | 325 | 405 | 84 | 530 | 660 | 95 |

| Max. Torque (Nm) | T Kmax | 34 | 42 | 12 | 120 | 150 | 35 | 320 | 400 | 85 | 650 | 810 | 170 | 1060 | 1350 | 190 |

| Overall Length (mm) | A | 66 | 78 | 90 | 114 | 126 |

| Outside Diameter (mm) | B | 42 | 56 | 66.5 | 82 | 102 |

| Outside Diameter with screw head (mm) | Bs | 44.5 | 57 | 68 | 85 | 105 |

| Mounting length (mm) | C | 25 | 30 | 35 | 45 | 50 |

| Inside diameter range H7 (mm) | D1/2 | 8-25 | 12-32 | 19-36 | 20-45 | 28-60 |

| Inside diameter of elastomer | DE | 19.2 | 26.2 | 29.2 | 36.2 | 46.2 |

| Clamping screw ISO 4762 | E | M5 | M6 | M8 | M10 | M12 |

| Tightening Torque of clamping screw (Nm) | E | 8 | 15 | 35 | 70 | 120 |

| Distance between centerlines (mm) | F | 15.5 | 21 | 24 | 29 | 38 |

| Distance (mm) | G | 8.5 | 10 | 12 | 15 | 17.5 |

| Hub length (mm) | H | 39 | 46 | 52.5 | 66 | 73 |

| Download - 2D .dxf - COMING SOON | ||||||

| Download - 3D .STP | STP | STP | STP | STP | STP | |

| For Full Tech Details Download Catalog | ||||||

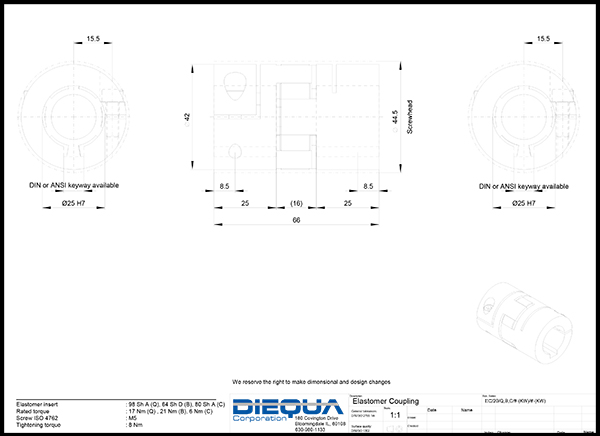

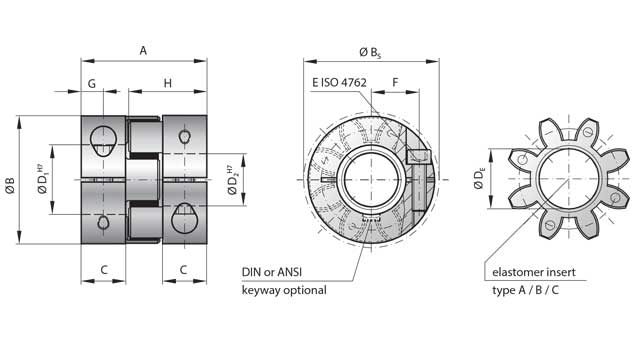

MODEL ECC – Elastomer Coupling with Compact Clamping Hub

Design Description: Two concentrically machined hubs with single screw clamping connection. Our most compact design!

Bore Diameters: Metric or inch bores from 4-60 mm, or 0.16-2.36 inches. Keyways are optional, but not necessary.

Hub Materials: Size 5-450 in high-strength aluminum. Stainless steel available for all sizes upon request.

Rated Speed: Up to 4,000 RPM standard. Higher with balancing.

Temperature Range: Download the catalog for Temperature range.

Sizes: ECC-5, ECC-10, ECC-20, ECC-60, ECC-150, ECC-300, ECC-450

Application Example:

Sizing Chart:

| ECC | 5 | 10 | 20 | 60 | 150 | 300 | 450 | |

|---|---|---|---|---|---|---|---|---|

| Type (Elastomer Insert) | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | |

| Rated torque (Nm) | T KN | 9 | 12 | 2 | 12.5 | 16 | 4 | 17 | 21 | 6 | 60 | 75 | 20 | 160 | 200 | 42 | 325 | 405 | 84 | 530 | 660 | 95 |

| Max. Torque (Nm) | T Kmax | 18 | 24 | 4 | 25 | 32 | 6 | 34 | 42 | 12 | 120 | 150 | 35 | 320 | 400 | 85 | 650 | 810 | 170 | 1060 | 1350 | 190 |

| Overall Length (mm) | A | 26 | 32 | 50 | 58 | 62 | 86 | 94 |

| Outside Diameter (mm) | B | 25 | 32 | 42 | 56 | 66.5 | 82 | 102 |

| Outside Diameter with screw head (mm) | Bs | 25 | 32 | 44.5 | 57 | 68 | 85 | 105 |

| Mounting length (mm) | C | 8 | 10.3 | 17 | 20 | 21 | 31 | 34 |

| Inside diameter range H7 (mm) | D1/2 | 4-12.7 | 4-16 | 8-25 | 12-32 | 19-36 | 20-45 | 28-60 |

| Inside diameter of elastomer | DE | 10.2 | 14.2 | 19.2 | 26.2 | 29.2 | 36.2 | 46.2 |

| Clamping screw ISO 4762 | E | M3 | M4 | M5 | M6 | M8 | M10 | M12 |

| Tightening Torque of clamping screw (Nm) | E | 2 | 4 | 8 | 15 | 35 | 70 | 120 |

| Distance between centerlines (mm) | F | 8 | 10.5 | 15.5 | 21 | 24 | 29 | 38 |

| Distance (mm) | G | 4 | 5 | 8.5 | 10 | 11 | 15 | 17.5 |

| Hub length (mm) | H | 16.7 | 20.7 | 31 | 36 | 39 | 52 | 57 |

| Download - 2D .dxf - COMING SOON | ||||||||

| Download - 3D .STP | STP | STP | STP | STP | STP | STP | STP | |

| For Full Tech Details Download Catalog | ||||||||

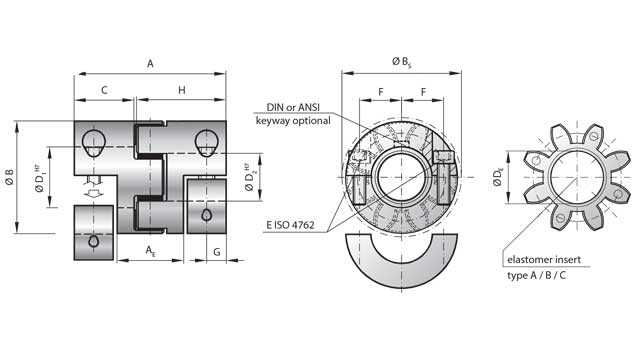

Model ECS - Elastomer Insert Coupling with Split Clamping Hub

Design Description: Has removable, concentrically machined, hub halves for easy mounting.

Bore Diameters: Metric or inch bores from 6-60 mm, or .23 – 2.36 inches. Keyways are optional, but not necessary.

Hub Materials: High-strength aluminum. Stainless steel available for all sizes upon request.

Rated Speed: Up to 4,000 RPM standard. Higher with balancing.

Temperature Range: Download the catalog for Temperature range.

Sizes: ECS-10, ECS-20, ECS-60, ECS-150, ECS-300, ECS-450

Application Example:

Sizing Chart:

| ECS | 10 | 20 | 60 | 150 | 300 | 450 | |

|---|---|---|---|---|---|---|---|

| Type (Elastomer Insert) | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | |

| Rated torque (Nm) | T KN | 12.6 | 16 | 4 | 17 | 21 | 6 | 60 | 75 | 20 | 160 | 200 | 42 | 325 | 405 | 84 | 530 | 660 | 95 |

| Max. Torque (Nm) | T Kmax | 25 | 32 | 6 | 34 | 42 | 12 | 120 | 150 | 35 | 320 | 400 | 85 | 650 | 810 | 170 | 1060 | 1350 | 190 |

| Overall Length (mm) | A | 53 | 66 | 78 | 90 | 114 | 126 |

| Length of Center Section (mm) | AE | 20 | 28.8 | 34 | 38 | 50 | 52 |

| Outside Diameter with screw head (mm) | Bs | 32 | 42 | 56 | 66.5 | 82 | 102 |

| Mounting length (mm) | C | 20 | 25 | 30 | 35 | 45 | 50 |

| Inside diameter range H7 (mm) | D1/2 | 6-16 | 8-25 | 12-32 | 19-36 | 20-45 | 28-60 |

| Inside diameter of elastomer | DE | 14.2 | 19.2 | 26.2 | 29.2 | 36.2 | 46.2 |

| Clamping screw ISO 4762 | E | 4xM4 | 4xM5 | 4xM6 | 4xM8 | 4xM10 | 4xM12 |

| Tightening Torque of clamping screw (Nm) | E | 4 | 8 | 15 | 35 | 70 | 120 |

| Distance between centers (mm) | F | 10.5 | 15.5 | 21 | 24 | 29 | 38 |

| Distance (mm) | G/G1 | 7.5 | 8.5 | 10 | 12 | 15 | 17.5 |

| Hub length (mm) | H/H1 | 31 | 39 | 46 | 52.5 | 66 | 73 |

| Download - 2D .dxf - COMING SOON | |||||||

| Download - 3D .STP | STP | STP | STP | STP | STP | STP | |

| For Full Tech Details Download Catalog | |||||||

Model ECX - Elastomer Intermediate Spacer

Design Description: A concentrically machined spacer with curved jaws. 2x elastomer segments press fit for zero backlash; standard versions are electrically isolating.

Sizes: ECX-5, ECX-10, ECX-20, ECX-60, ECX-150, ECX-300, ECX-450

Sizing Chart:

| ECX | 5 | 10 | 20 | 60 | 150 | 300 | 450 | |

|---|---|---|---|---|---|---|---|---|

| Type (Elastomer Insert) | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | |

| Rated torque (Nm) | T KN | 9 | 12 | 2 | 12.5 | 16 | 4 | 17 | 21 | 6 | 60 | 75 | 20 | 160 | 200 | 42 | 325 | 405 | 84 | 530 | 660 | 95 |

| Max. Torque (Nm) | T Kmax | 18 | 24 | 4 | 25 | 32 | 6 | 34 | 42 | 12 | 120 | 150 | 35 | 320 | 400 | 85 | 650 | 810 | 170 | 1060 | 1350 | 190 |

| Overall Length (mm) | A | 26 | 30 | 39 | 48 | 53 | 62 | 86 |

| Outside Diameter (mm) | B | 25 | 32 | 42 | 56 | 66.5 | 82 | 102 |

| Hub length (mm) | C | 9 | 9 | 10 | 16 | 18 | 20 | 40 |

| Inside diameter (mm) | D | 15 | 18 | 25 | 32 | 38 | 45 | 60 |

| Inside diameter of elastomer (mm) | DE | 10.2 | 14.2 | 19.2 | 26.2 | 29.2 | 36.2 | 46.2 |

| Moment of Inertia (10-3 kgm2) | J1/J2 | 0.0005 | 0.002 | 0.008 | 0.03 | 0.05 | 0.1 | 0.6 |

| Download - 2D .dxf - COMING SOON | ||||||||

| Download - 3D .stp - COMING SOON | ||||||||

| For Full Tech Details Download Catalog | ||||||||

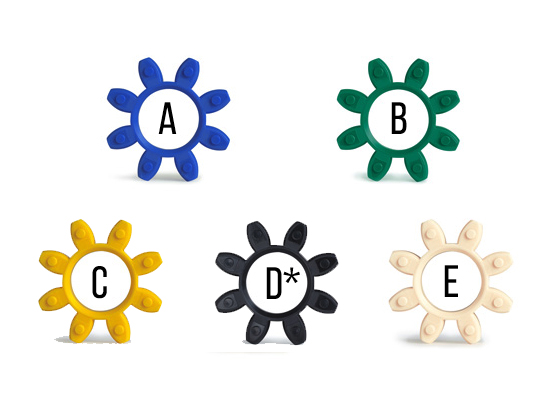

Coupling Insert Options, Temperature Ranges, and Stiffness Ratings:

The elastomer inserts are made of thermoplastic polyurethane (TPU), in a variety of shore values. To provide different stiffness and vibration damping characteristics, optional Hytrel® material can be offered for higher temperature applications.

The inserts are pre-stressed during assembly which provides zero backlash, more consistent load sharing, and improved restoring forces for precise positioning and repeatability.

For information on shaft misalignment, torsional stiffness and other details about the elastomer inserts, please download the catalog.

* Due to the electrically conductive properties of the insert, electrostatically charging of the coupling is prevented. This eliminates sparks during normal operation in explosive areas. Technical data is available upon request.

The values of the relative damping were determined at 10 Hz and 20˚C.

Compensates for Misalignment

The elastomer insert jaw coupling can compensate for axial, lateral (parallel), and angular misalignment. This aids in assembly and reduces load stress on drive bearings. It is important to consider the maximum values highlighted in the catalog to avoid premature wear of the elastomer element. In order to see these values please download the catalog.

Ordering Examples & Part Number Definitions

Other Models Available

Why Choose an Elastomer Jaw Coupling?

These couplings are ideal for maintaining position control while absorbing shocks and vibration. They are an economical solution where the extra cost of bellows or disc designs are not warranted.