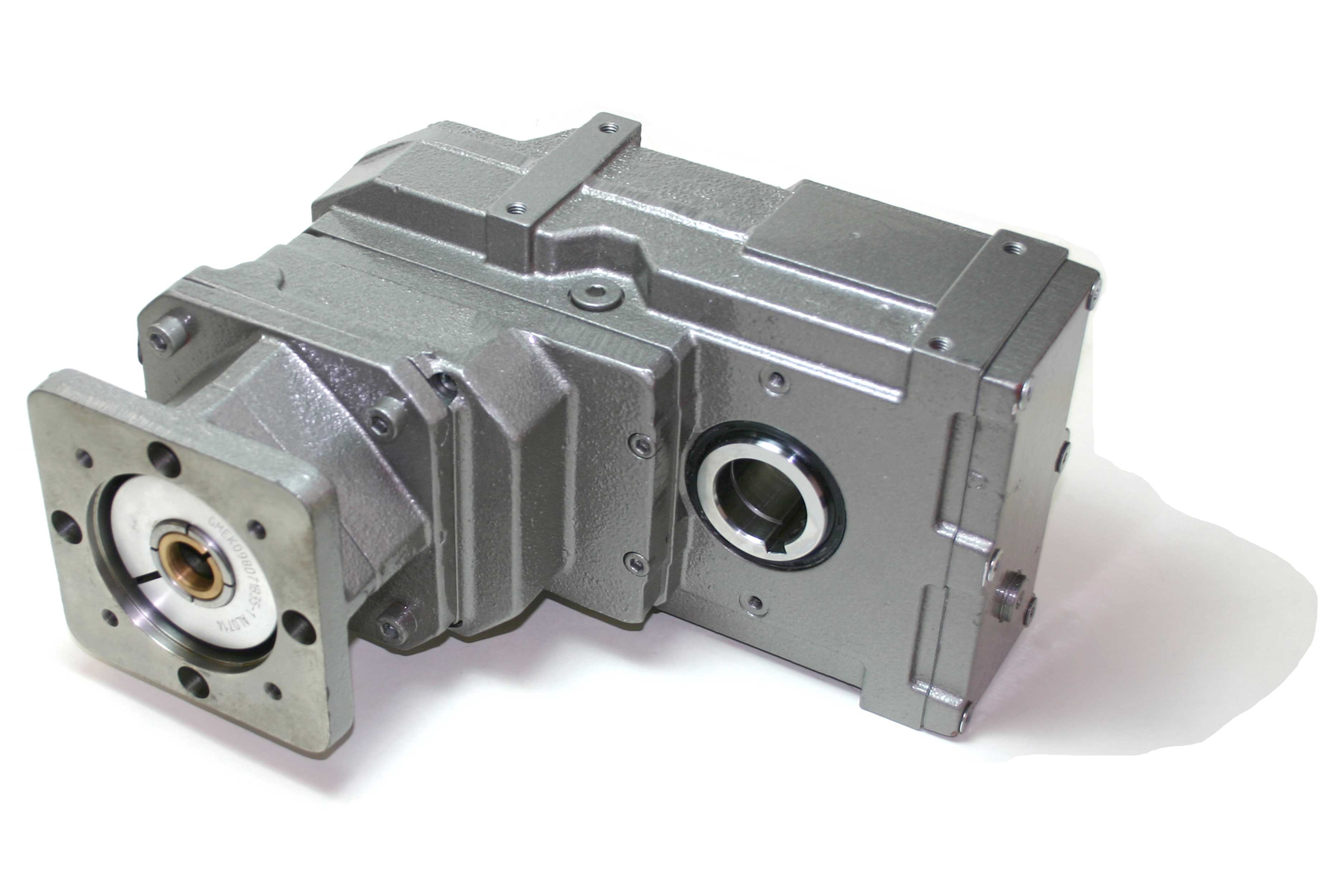

High Torque Helical Inline Servo Gearheads

The H Series Helical Inline Servo Gearbox provides unmatched performance, durability, and design flexibility. Evolving from our standard line of premium quality speed reducers, these reduction gearboxes offer higher torque capacities than planetary gearheads, up to 14,000 Nm (10,325 ft lbs.). These high-torque reduction gearboxes are ideal for moderately dynamic motion profiles at price points far below comparably sized Servo Planetary boxes.

- 14 sizes

- Gear ratios from 3.6:1 to 468:1

- Torque capacities to 14,000 Nm (10,325 ft lbs)

- Class 12 Helical Gears: provides higher efficiencies and greater torques in smaller sizes.

- Two servo motor shaft adapter styles available for either a smooth motor shaft or a keyed motor shaft configuration.

- Multiple Output Options: Inch and metric output shafts, mounting pilots and flanges offer a wide range of design solutions.

- UNIBLOCK Housing: For maximum rigidity.

- Low Backlash for Precise Motion: Backlash as low as 5 arc minutes is possible for quick response and accurate positioning.

- Reducer efficiencies as high as 95%

- Servo motor interface flanges: 100 mm to 220 mm, other sizes available.

What’s Next?

Other Models Available

Related Products

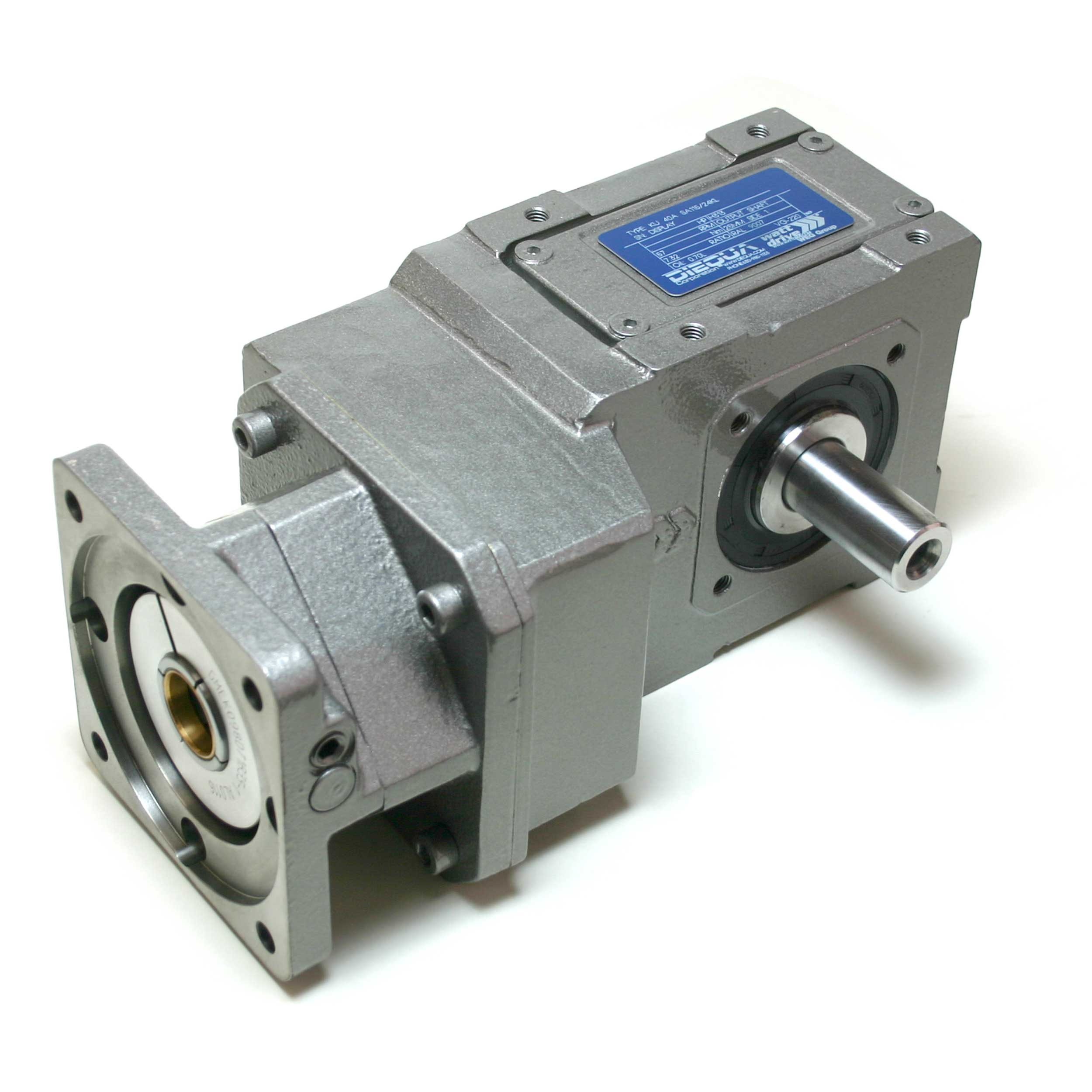

The WATT Drive series of helical gearing servo gearheads provides economical motion and speed control with a variety of inline and right angle helical, helical bevel, and helical worm designs.

Mounting Options

Output Shaft Options

Why Choose a High Torque Servo Gearhead?

The WATT modular drive system, know as the WATT MAS system, is only gearbox and gear-motor program built using a building block system. This unique construction style allows all the various types of gearboxes to use the same input gear sets and, in most cases, the same output hollow bores, solid shafts, and flanges. The input can be with either an integrated WATT EUSAS motor or a variety of adapters including IEC, NEMA, or Servo. The WATT EUSAS motor is another innovation from the WATT engineering team. This UL, CSA, CE and AEC certified motor is also built using the same modular building block system. All these motors are inverter duty rated and have multi volt/Hz terminal blocks. This allows one motor to be used virtually anywhere in the world without requiring different windings. The back side of the motor has a modular end bell to accept brakes, encoders, or forced cooling by themselves or in any combination.

DieQua is the exclusive and only North American Assembly Center for the WATT MAS program. We have an extensive inventory to be able to react quickly to build, test, paint, and ship any standard product from the WATT MAS system. Using our own manufacturing capacity we are also uniquely capable of modifying or creating special designs. Call or email and let us create something for you.