Precision Servo Worm Gearheads

Our right-angle servo worm gearboxes provide high-precision rotary motion for highly dynamic cyclical or speed control servo applications.

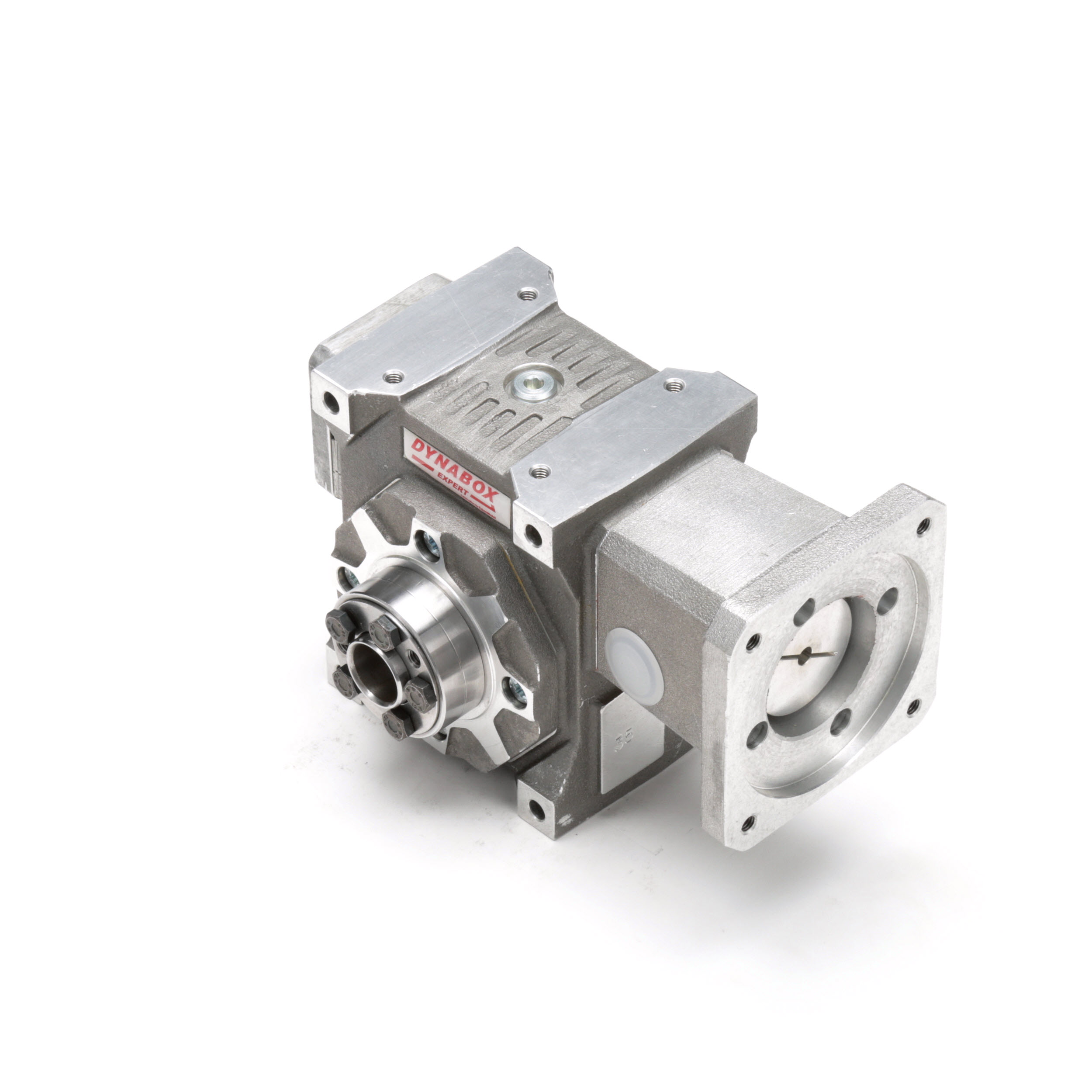

These Dynabox high-precision servo worm gearboxes are available in 3 backlash levels to satisfy a variety of applications. Output options include single and dual shafts, hollow bore with keyway, hollow bore with shrink disc, and rotary output flanges.

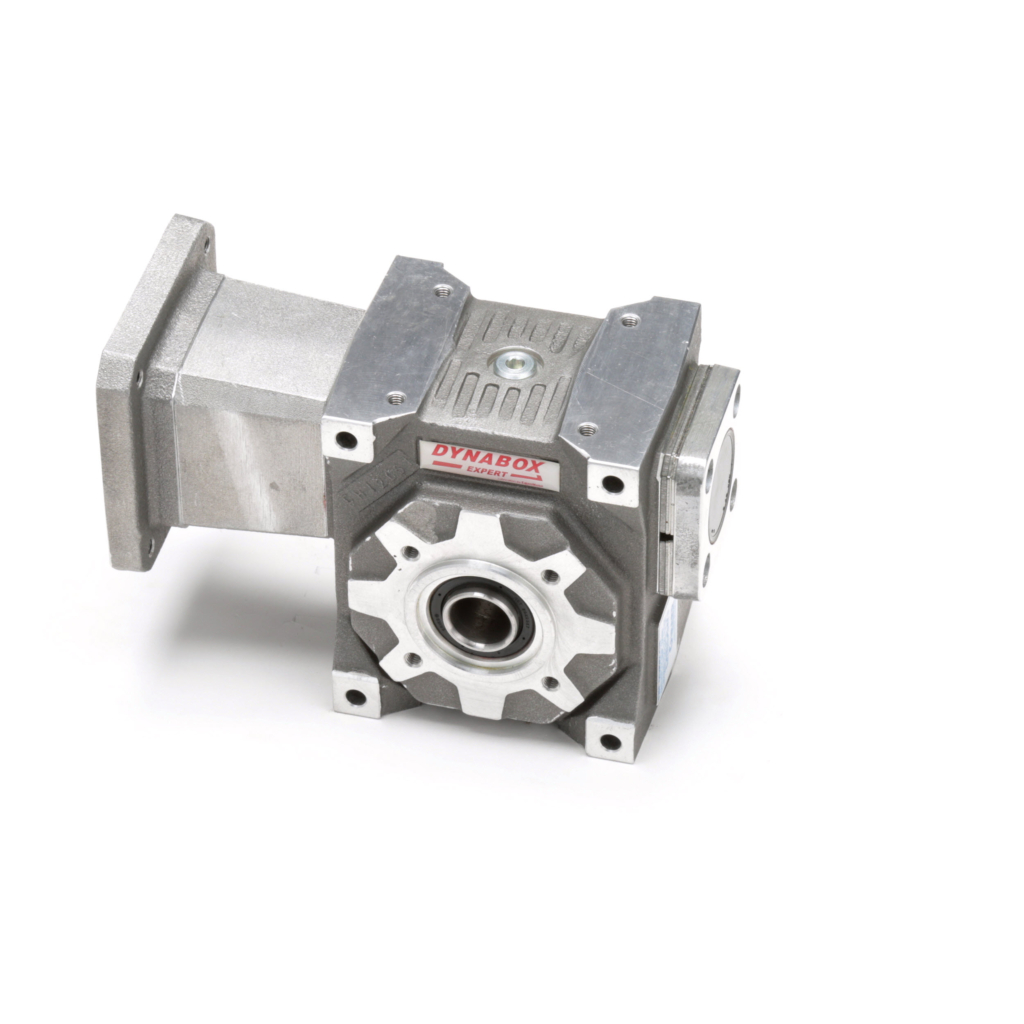

Standard Series – High-Precision Servo Worm Gearbox

(8 sizes with capacities to 1500 Nm)

-

-

- 9 exact ratios from 5.2:1 to 90:1

- Housings are made from aluminum-magnesium alloy.

- Three levels of backlash precision: Expert < 1 arc minute, Medium < 5 arc minutes, Basic < 10 arc minutes

-

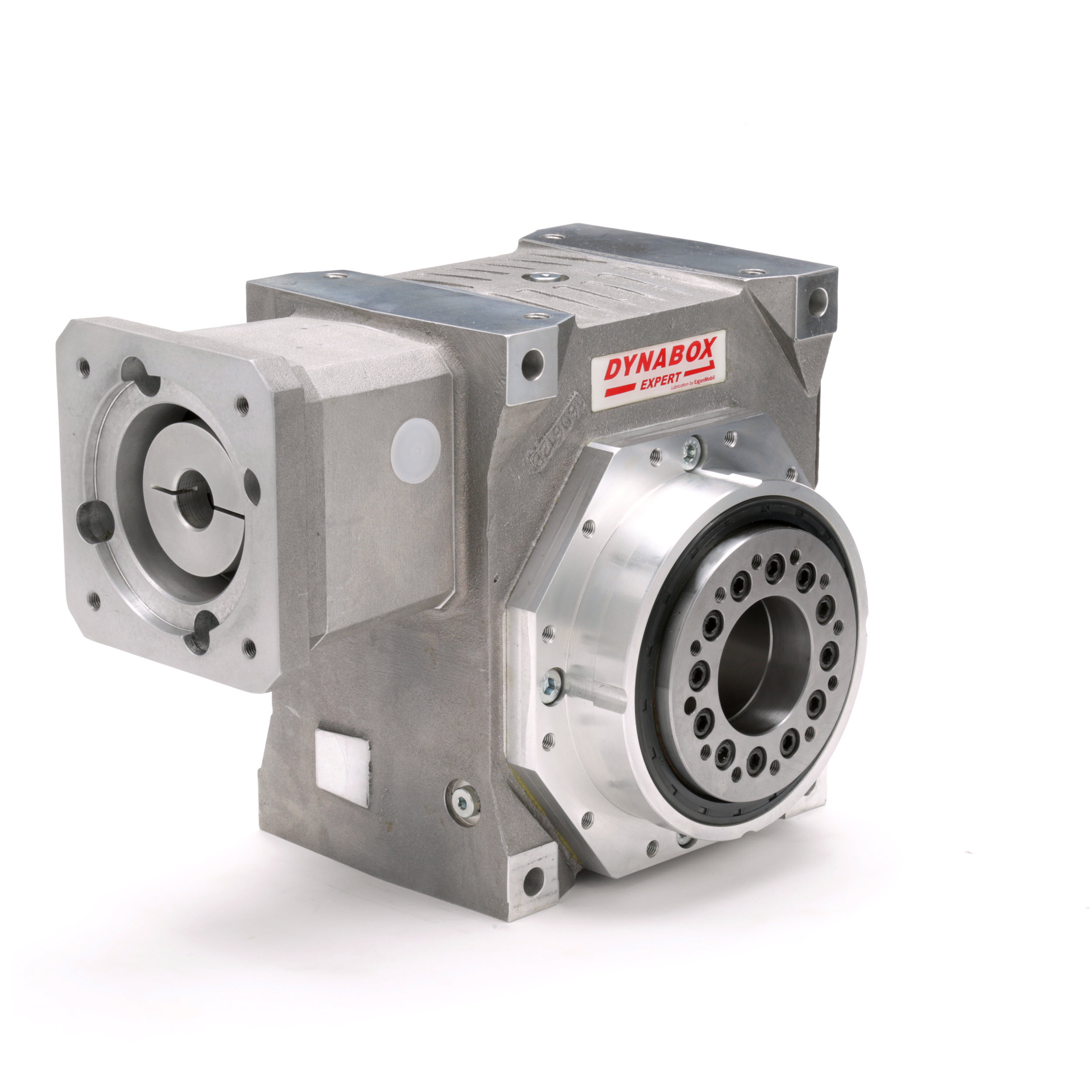

XL Series – High-Precision Servo Worm Gearbox

(3 sizes with capacities to 7500 Nm)

-

- 9 exact ratios from 5.125:1 to 90:1

- Housings made from cast iron.

- Two levels of backlash precision: Expert < 0.5 arc minutes, Medium < 5 arc minutes

- Low Backlash – 3 levels of backlash from 10 arc minutes to less than 1 arc minute assures the proper repeatability for your application.

- Multiple Output Options – Available in single or double output shafts, hollow bore with keyway, hollow bore with shrink disc, and rotary output flanges.

- Universal Motor Mounting – Provided with an adapter for virtually all servo motors and a torsionally rigid-flexible coupling for optimum motor shaft alignment.

- Optimized Gearing – Hardened and ground worms and bronze alloy wheels provide with unique dual compound ground gear flanks that deliver high torque, smooth operation, and superior shock absorption.

- Higher Radial Load Capacity – Oversized taper roller bearings accommodate high radial forces.

- Lower Noise – Precision worm gearing provides noise levels below 55 dB.

- Aluminum Alloy Housings – A hardened aluminum-magnesium alloy housing results in lower weight and higher torsional rigidity. XL series is cast iron for high strength.

- Constant Worm Bearing Preload – A unique 3-bearing arrangement on this high-precision gearbox maintains proper worm-bearing preload overall allowable temperature ranges.

- Gearhead Mounting Options – Tapped holes, through holes, and centering flanges maximize gearhead integration.

What’s Next?

Other Models Available

Why Choose a Precision Servo Worm Gearhead?

For simply two reasons: price and performance. Many engineers shy away from right angle designs because of the typical high cost. Two stage bevel planetary configurations can get expensive.

The Basic model servo worm can achieve up to 90:1 in a single stage and can be provided with several output options for more design versatility. This gives you back the space you need for a much lower cost.

And for super low backlash? The Expert model is perfect for quiet, precise rotary motion, limiting gear play to less than 1 arc minute.