Installation Instructions

| Product | Installation Tips Link |

|---|---|

| ServoFoxx Gearheads | Download PDF [868 KB] |

| Sesame Servo Gearheads) | Download PDF [6 MB] |

| Varvel Servo Gearheads | Download PDF [1.8 MB] |

| Tandler Speed Reducers | Click Here |

| WATT Speed Reducers | Download PDF [3.7 MB] |

| Spiral Bevel Gearboxes | Click Here |

| Cycloidal Reducers | Click Here |

| Screwjacks | Download PDF [2 MB] |

| Couplings - Metal Bellows, Series BC | COMING SOON |

| Couplings - Elastomer Insert, Series EC | COMING SOON |

| Lineshafts - Series L | COMING SOON |

Above, you will find our library of PDFs for industrial gearhead-to-gearbox installation, assembly, and maintenance. Typically, what we see in the industry is a horizontal mounting of servo gear heads on the machine itself. Because of this, it may be more natural for technicians to want to mount the motor and mount in a horizontal orientation, but this is not ideal.

When examining the individual components that need to connect, such as the machined pilot on the motor and the corresponding bore and flange on the gearbox, it’s important to note that these are precision-machined parts. These components have specific tolerance fields in their production. On the motor side, the components feature a minus tolerance, meaning the diameter can vary within a specified tolerance range, potentially being slightly smaller.

Conversely, the pilot-bore can be on the larger end of its tolerance range. If both components are manufactured at the extremes of their tolerances, they might technically meet specifications, but horizontal mounting could lead to maximum misalignment. This occurs as the motor tends to settle at the lowest point of the bore in the flange. Consequently, this alignment increases loads due to lateral misalignment, potentially reducing the lifespan of the components.

Industrial Gearbox Maintenance Tips

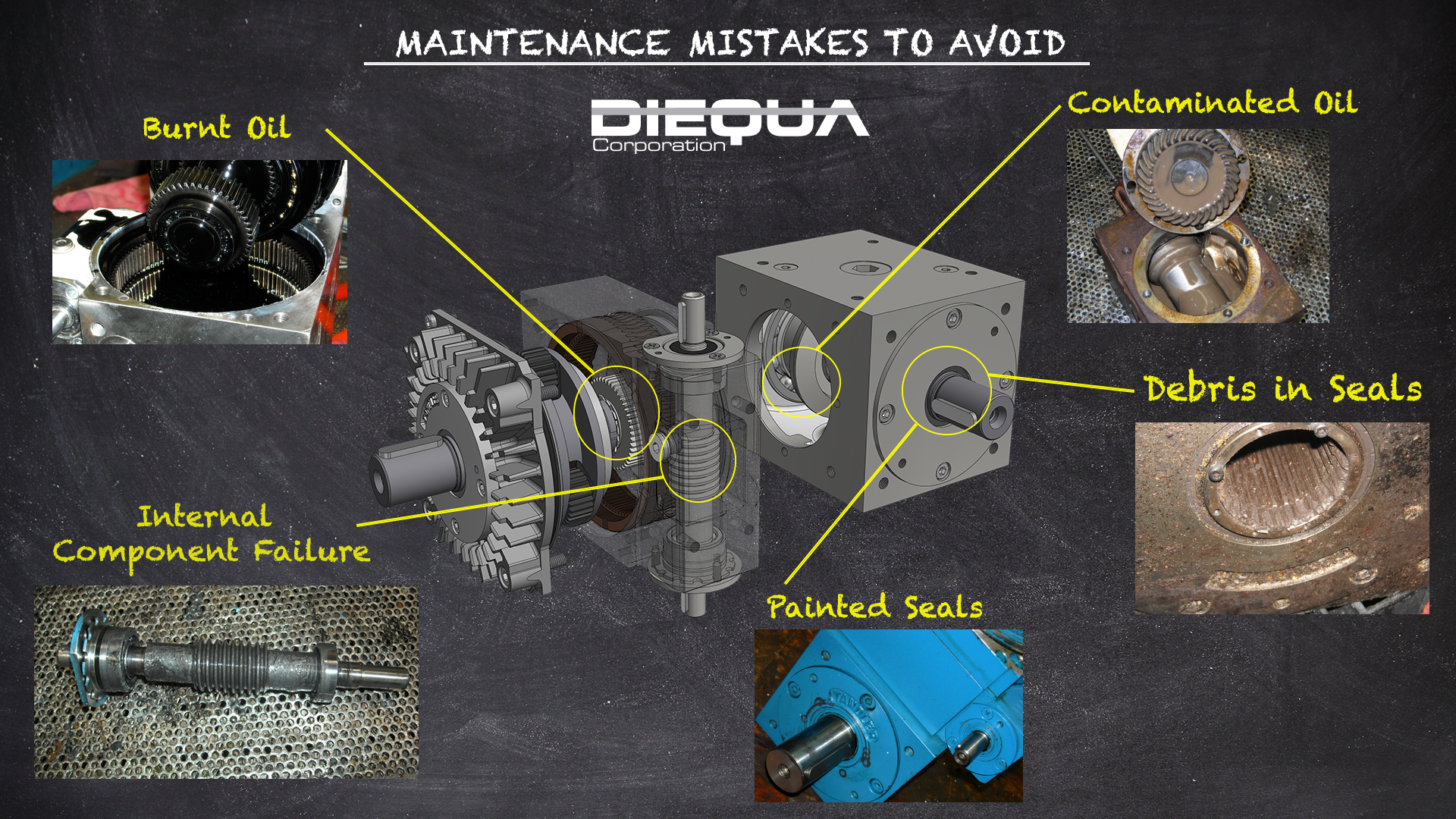

View our list of gearbox maintenance tips for mistakes to avoid.

In this list of avoidable industrial gearbox maintenance mistakes, DieQua provides both the common mistake as well as the best preventative measure.