Mixing and agitating applications pose demanding challenges for food industry gearboxes. Not only do speeds and loads vary significantly, but they also operate under harsh environmental conditions. Consequently, high-quality components, robust designs, and specialized protective features are essential.

We had a customer approach us with a challenge: they needed a robust industrial mixer gearbox capable of converting food solids into semi-liquids, suitable for products like spreads, cheese dips, ice cream, and pie filling. The requirements included two mixer sizes with capacities of 20 and 50 horsepower, operating at a full motor speed of 1750 rpm. Despite trying several food industry gearbox suppliers, none of their previous gearboxes lasted more than a few months under the demanding conditions of the process.

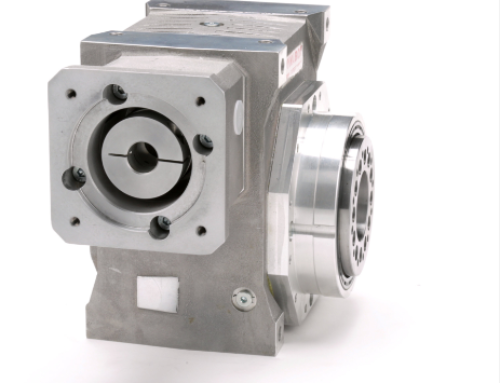

The basic design featured a large bowl with the mixing impeller shaft exiting through the bottom via a seal. The impeller shaft was to be connected to a hollow-shaft bevel gearbox, driven by the motor. Liquids and solids were introduced into the bowl, in a pre-determined fashion, and mixed accordingly.

The mixing process was extremely dynamic, with initial shock loads and varying torque requirements as the mixture transformed. Radial loads were also experienced as the impeller blades were positioned some distance from the gearbox-bearing seats.

The environmental conditions posed additional challenges; machine washdowns were required after each batch, and any leakage from a worn bowl seal would drip down along the impeller shaft onto the mixer gearbox seal, which was further complicated by the presence of abrasive crystals in many products.

We provided Tandler spiral bevel gearboxes for these industrial food mixers. Although typically known for high precision, it was the design’s inherent ruggedness that made them suitable for demanding power transmission applications in food processing.

To no one’s surprise, standard industrial spiral bevel gearboxes use standard industrial spiral bevel gears. While adequate for continuous high torque duty at slower speeds, the high torque shocks in this food industry gearbox application revealed a problem with these designs.

Because of the lower-quality gears used in the previous gearboxes, shock loads were focused on the high points of the gear flanks, generating excessive forces on very small areas and causing material fatigue. The higher quality lapped as a matched set; spiral bevel gears used in the Tandler gearboxes distributed shock loads over a wider area of the tooth surface. This allowed the full strength of the gears to be utilized, eliminating shock failure and extending gear life dramatically.

To accommodate the wash-down requirement, all these food industry gearboxes were coated with two-part white epoxy paint to resist corrosion and the harsh chemicals used in the cleaning process. A stainless seal shield was also added to the upper vertical shaft to deflect direct washdown spray and protect the mixer gearbox shaft seal from any abrasive product that might leak from the bowl seal above.

Although this solution was more expensive than previous gearboxes, the life of this food industry gearbox was extended four to five times, significantly reducing service costs and maintaining the viability of the machine design. The alternative would have been to discontinue the mixer line.

While the Tandler gearbox is more often used in applications requiring precise motion control, it is also used in a wide variety of applications requiring extremely heavy-duty power transmission. The premium quality components used and the precise assembly tolerances make the design ideal for satisfying extremely demanding operational requirements.

The Tandler spiral bevel gearbox program offers the widest range of ratios, shaft configurations, and special options available. Dimension modifications and complete special designs are also possible for quantities as small as one piece. A variety of wash-down and extreme environmental conditions protection options are also available to satisfy requirements for industries needing these types of design elements.

So, whether you have an application requiring precise motion control or one that requires extremely rugged, reliable power transmission, there is a Tandler spiral bevel gearbox that can handle the job. Please contact your DieQua representative for additional information.