IEC vs. NEMA Motors

A large percentage of our customers produce their machinery for both the North American domestic market as well as for the various export markets of Europe, Asia, and South America. This often causes a design issue as power sources are different from market to market. Different motors should be specified to optimize the design, which then alters the gearboxes used with them. Most of our gear products have a solution for that complexity. Here is an example of one of those gearbox products when it came to IEC vs. NEMA motors.

We recently met with a machinery manufacturer who wasn’t thrilled with his worm gearbox situation. It doesn’t matter what kind of machinery he made as this story relates to all those OEMs selling in similar markets.

As our contact told us, it wasn’t so much that he had technical or quality issues. It was that he had problems with maintaining the correct inventory he needed.

You see, this manufacturer had a history of selling his machines in the domestic North American market but was also seeing tremendous growth in his exports after launching an international division. This led to a conundrum.

Since they started selling domestically for some time before expanding overseas all his gearboxes were typically NEMA AC motor-driven with inch-dimensioned output shafts. Especially in some old-line industries, this is more the norm than not. However, in their new export markets, the customers wanted IEC frame motors and metric shafts to allow for easier local service.

Because worm speed reducers typically have quill inputs for motor shaft insertion the customer needed two different gearboxes for the same machine, depending on where it was going. Hence, a requirement for a higher inventory level to ensure parts availability.

Aha, an undetected fixable problem/irritation! The customer just figured he didn’t have a choice and went about buying both types of gearboxes. But we had a solution that would save him a bundle.

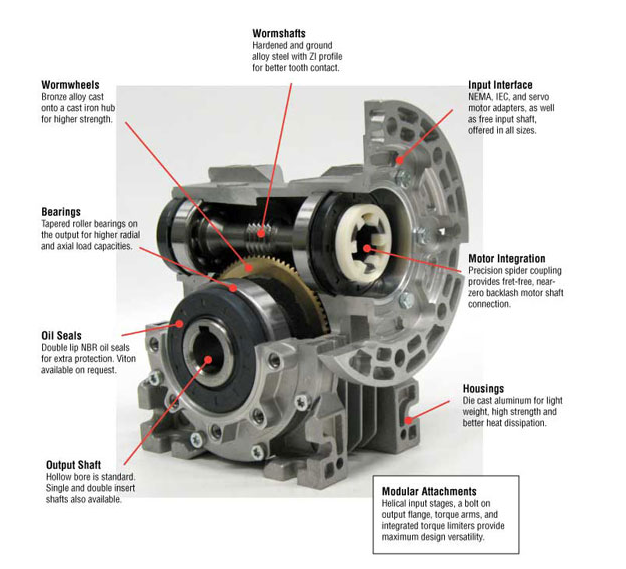

We offered as an alternative our Varvel brand of worm speed reducer gearbox. How would this help the customer’s situation? Its design is ideal for satisfying metric and inch-dimensioned markets with minimal inventory.

The Varvel worm speed reducer is designed with an integrated flexible jaw coupling as its input. There isn’t a dedicated quill input. Among other benefits, the input motor adapter hub comes in both inch and metric dimensions equal to IEC and NEMA motor standards.

Also for accommodating the two motor standards, motor adapter plates are interchangeable. So, to switch from a NEMA motor to an IEC motor is just a matter of selecting a different motor adapter plate and hub.

The hollow output shaft comes in either inch or metric dimensions, which may limit this infinite interchangeability somewhat when shaft mounting. However, this customer was driving a pulley and therefore needed an output shaft. We simply offered to machine the end of an insert shaft to one dimension for the bore and the output side to either a metric or inch dimension.

Okay, does this eliminate his problem of extra inventory? Of course not. He needs two motors, two adapter plates, two hubs, and two output shafts. However, what he needs only is his gearbox. This was an expensive element within his machine design and reducing inventory on this part made for some significant savings.

Because we are probably the only manufacturer integrating this kind of input design in a worm gearbox the customer didn’t really think to look for this solution. But there it unexpectedly was.

It was through the customer sharing their situation and goals that we were able to help them identify their “pain” even though they didn’t realize it exactly. Too many designers want to hold too much information close to their vest. I suggest you share more information with your suppliers, not less. That is how you can get the most out of them.

As previously stated, the coupling design has many other performance benefits in addition to interchangeable input configurations. Click on worm speed reducers to see all the design features and the benefits you can derive from them. Or just give our gearbox consultants a call.