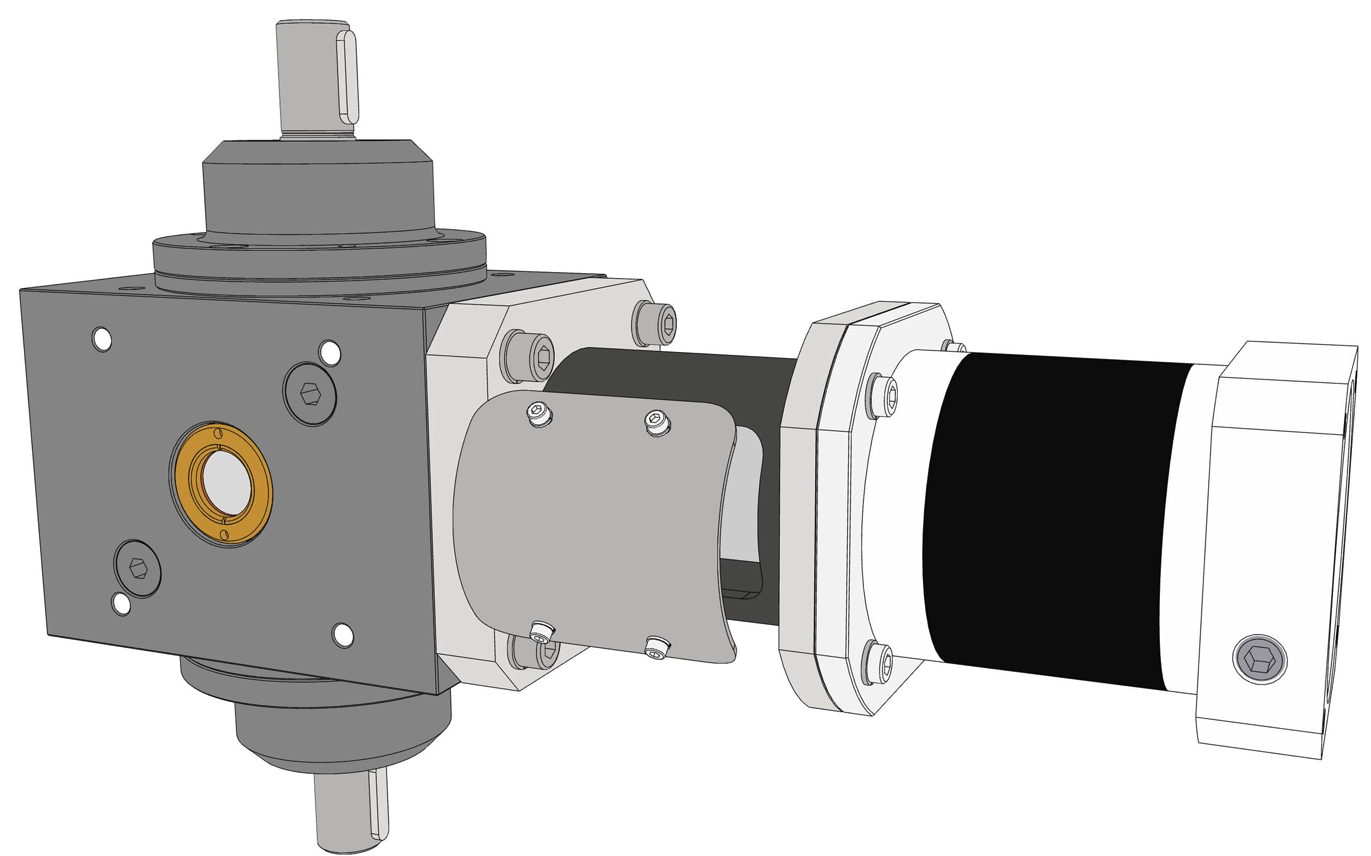

Baked Gearbox

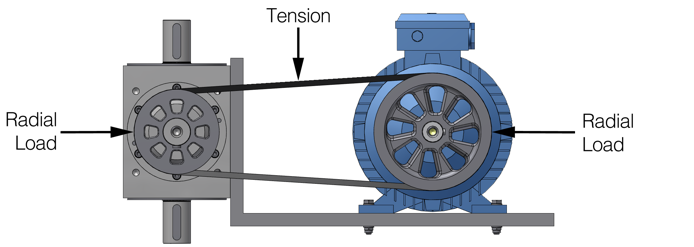

With Summer’s heat approaching, it’s time to discuss an extreme environment application. High-temperature engineering solutions are required in many industries. A customer recently came to us with an application for operating a painting fixture. The fixture was to hold aircraft parts for the U.S. Air Force. The basic design called for an inline helical speed reducer that would drive, what amounted to, a rotisserie device that would slowly rotate the part so that all surfaces were easily accessible. While it was relatively a straightforward application, there were some critical caveats. The first was a [...]